-

StevenCHN-TOP offer very good service and the products help us a lot

StevenCHN-TOP offer very good service and the products help us a lot -

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines -

MikeBest products with best price, CHN-TOP well done!

MikeBest products with best price, CHN-TOP well done!

Automatic Vacuum Brazing Machine The Ultimate Solution for PCD/PCBN Inserts Brazing

| Vacuum Process | 1.Cleaning,2. Fixiing Flux,3.Drying At The Temperature Of 200℃ For 30mins,4.Brazing | Chamber | Quartz Glass Tube |

|---|---|---|---|

| Chamber Size | 180*500mm | Brazing Capability | CNGA1204 Appr. 600pcs/cycle |

| Max Temperature | 950° | Power Supply | 380V-3Phases-5Wires/20KW |

| Weight | 600kg | Machine Type | Vacuum Welding/Brazing Machine |

| Highlight | Automatic Vacuum Brazing Machine,PCBN Inserts Brazing Machine,PCD Inserts Brazing Machine |

||

Product Description:

The High Temperature Vacuum Welder is a top-of-the-line Vacuum Brazing System designed for brazing ultra hard materials such as PCD and PCBN inserts. This advanced machine offers precision and efficiency for various industrial applications.

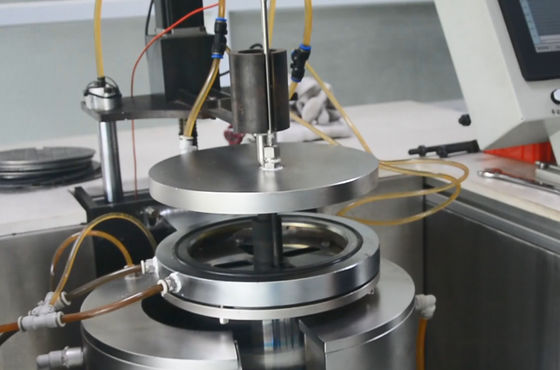

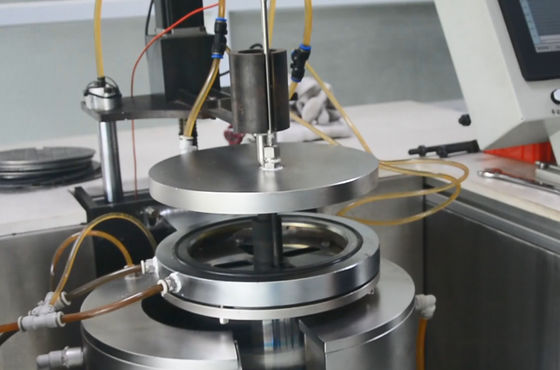

The main chamber of the Vacuum Brazing Machine is constructed with a durable Quartz Glass Tube, ensuring high visibility and resistance to high temperatures. With a weight of 600kg, this machine is robust and stable, providing a reliable platform for brazing operations.

Powered by a 380V-3Phases-5Wires/20KW power supply, the Vacuum Brazing Machine delivers consistent and powerful performance to meet the demands of high-temperature brazing processes. The power supply configuration ensures stable energy supply for efficient operation.

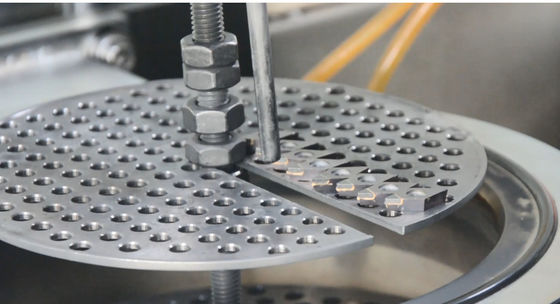

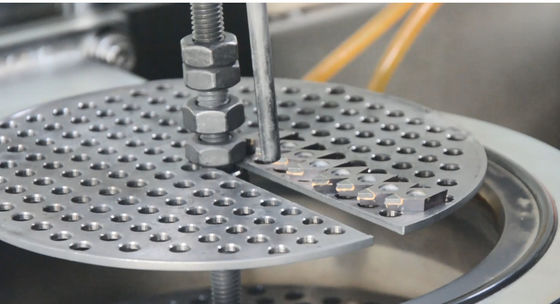

Specifically designed for PCD and PCBN inserts brazing, this Vacuum Brazing System excels in handling ultra hard materials with precision and care. The machine's vacuum process involves several key steps to ensure optimal brazing results:

- Cleaning: The first step in the vacuum process involves thorough cleaning of the materials to be brazed, ensuring a clean and secure joint.

- Fixing Flux: The next step is the application of flux to the materials, which helps facilitate the brazing process and improve the quality of the joint.

- Drying At The Temperature Of 200℃ For 30mins: Prior to brazing, the materials are dried at a specific temperature to remove any moisture and prepare them for the brazing process.

- Brazing: The final step involves the actual brazing process, where the materials are joined together under high temperature and vacuum conditions to create a strong and reliable bond.

With its comprehensive vacuum process and precise control capabilities, the High Temperature Vacuum Welder offers unmatched performance and efficiency in brazing ultra hard materials. Whether you are working with PCD or PCBN inserts, this Vacuum Brazing System is the ideal solution for achieving high-quality brazed joints.

Technical Parameters:

| Max Vacuum Rate | 10^-2 Pa |

| Vacuum Process | 1.Cleaning,2. Fixiing Flux,3.Drying At The Temperature Of 200℃ For 30mins,4.Brazing |

| Application | PCD/PCBN Inserts Brazing |

| Brazing Capability | CNGA1204 Appr. 600pcs/cycle |

| Chilling | Water Cooling |

| Guarantee | 1 Year |

| Heating Source | 18pcs Halogen Tubes |

| Chamber | Quartz Glass Tube |

| Chamber Size | 180*500mm |

| Machine Type | Vacuum Welding/Brazing Machine |

Applications:

The vacuum brazing system is specifically tailored for ultra hard materials such as PCD and PCBN inserts, making it ideal for industries requiring precise and durable brazing results. The chamber size of 180*500mm provides ample space for accommodating various workpieces.

Equipped with water cooling for efficient chilling, the CTSTC ZT-ZKHJ280 Vacuum Brazing Machine offers a maximum vacuum rate of 10^-2 Pa, ensuring a controlled and stable brazing environment for optimal results.

Whether in research laboratories or industrial settings, this vacuum brazing machine is suitable for a wide range of applications and scenarios. It is perfect for precision engineering tasks where the bonding of ultra hard materials is essential.

Customers can order this high-quality product with a minimum order quantity of 1, and the price is negotiable to suit different budget requirements. The packaging details include a sturdy plywood box for secure transportation.

With dimensions of L1600×W950×H900mm, the CTSTC ZT-ZKHJ280 Vacuum Brazing Machine is compact yet spacious enough for efficient operation. The delivery time is estimated to be 45-60 days, and payment terms accepted include TT, LC, and Western Union.

Customization:

Product Customization Services for the Vacuum Brazing Machine:

Brand Name: CTSTC

Model Number: ZT-ZKHJ280

Place of Origin: CHINA

Certification: CE

Minimum Order Quantity: 1

Price: Negotiable

Packaging Details: plywood box

Delivery Time: 45-60 days

Payment Terms: TT/LC/Western Union

Vacuum Process:

- 1. Cleaning

- 2. Fixing Flux

- 3. Drying At The Temperature Of 200℃ For 30mins

- 4. Brazing

Dimensions: L1600×W950×H900mm

Power Supply: 380V-3Phases-5Wires/20KW

Brazing Capability: CNGA1204 Appr. 600pcs/cycle

Chilling: Water Cooling

Keywords: Automatic Vacuum Machine for PCD/PCBN, Diamond Vacuum Brazing Device, Tungsten Carbide Vacuum Brazing Machine

Support and Services:

The Vacuum Brazing Machine product comes with comprehensive Product Technical Support and Services to ensure optimal performance and customer satisfaction. Our technical support team is available to assist with any product-related inquiries, troubleshooting, and maintenance guidance. Additionally, we offer a range of services such as installation support, training sessions, and periodic maintenance checks to keep your Vacuum Brazing Machine running smoothly.