-

StevenCHN-TOP offer very good service and the products help us a lot

StevenCHN-TOP offer very good service and the products help us a lot -

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines -

MikeBest products with best price, CHN-TOP well done!

MikeBest products with best price, CHN-TOP well done!

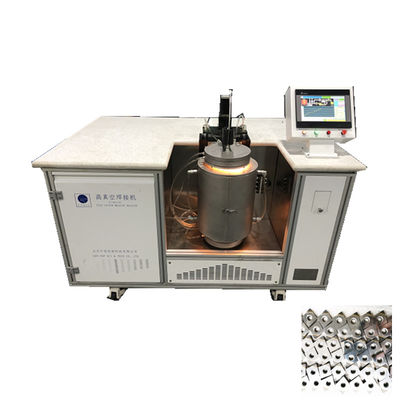

Automatic 950.C Vacuum Brazing Machine With Quartz Glass Tube And Halogen Heating Source

| Max Temperature | 950° | Guarranty | 1 Year |

|---|---|---|---|

| Dimensions | L1600×W950×H900mm | Operation Mode | Automatic |

| Machine Type | Vacuum Welding/Brazing Machine | Application | PCD/PCBN Inserts Brazing |

| Chamber | Quartz Glass Tube | Heating Source | 18pcs Halogen Tubes |

| Highlight | Halogen Heating Source Vacuum Brazing Machine,Quartz Glass Tube Vacuum Brazing Machine,Automatic Vacuum Brazing Machine |

||

Product Description:

The vacuum brazing process of this machine involves four steps. The first step is cleaning the materials to be brazed. This ensures that the surface is free from any contaminants that may affect the brazing quality. The second step is fixing the flux, which is essential in removing any oxide layers on the surface of the materials and promoting wetting during the brazing process. The third step is drying the materials at a temperature of 200℃ for 30 minutes. This removes any moisture that may cause porosity during the brazing process. The fourth and final step is brazing the materials.

This vacuum brazing machine is specifically designed for PCD/PCBN inserts brazing. With its automatic vacuum system, it ensures that the brazing process is done efficiently and effectively. The vacuum system is also responsible for preventing oxidation and reducing the brazing temperature, making the process more reliable and consistent.

The Automatic Vacuum Machine for PCD/PCBN Inserts Brazing is a reliable and cost-effective solution for your welding and brazing needs. Its high temperature vacuum welding capability and quartz glass tube chamber ensures the quality of the brazing process. With its 18 pieces of halogen tubes as the heating source, this machine guarantees a fast and efficient brazing process.

Technical Parameters:

| Heating Source | 18pcs Halogen Tubes |

| Dimensions | L1600×W950×H900mm |

| Guarantee | 1 Year |

| Chamber Size | 180*500mm |

| Machine Type | Vacuum Welding/Brazing Machine |

| Power Supply | 380V-3Phases-5Wires/20KW |

| Weight | 600kg |

| Operation Mode | Automatic |

| Max Vacuum Rate | 10^-2 Pa |

| Chamber | Quartz Glass Tube |

Applications:

The ZT-ZHKJ180 is capable of brazing CNGA1204 at approximately 600 pieces per cycle, making it a great choice for high-volume production scenarios. Despite its impressive capabilities, the machine is relatively lightweight at 600kg and has dimensions of L1600×W950×H900mm, making it easy to integrate into your existing production setup.

When it comes to power supply, the ZT-ZHKJ180 requires a 380V-3Phases-5Wires/20KW connection. It is delivered in a sturdy plywood box and has a delivery time of 45-60 days from the time of order. The minimum order quantity is 1, and the price is negotiable depending on the order quantity and payment terms.

With its vacuum welding and brazing capabilities, the ZT-ZHKJ180 is a versatile machine that can be used for a variety of applications. It is particularly well-suited for applications that require high-precision, high-strength bonding, such as in the automotive, aerospace, and electronics industries.

If you're in the market for a high-quality, reliable vacuum welding/brazing machine, the CTSTC ZT-ZHKJ180 is definitely worth considering. Contact us today to learn more about this fantastic product!

Support and Services:

The Vacuum Brazing Machine is designed to provide reliable and efficient brazing solutions for various industrial applications. Our technical support team is always available to assist you with any questions or issues you may encounter during the installation or operation of the machine.

We also offer comprehensive services to ensure your Vacuum Brazing Machine is running at its optimal performance, including regular maintenance, repair, and replacement of parts. Our skilled technicians are trained to diagnose and resolve any problems quickly and effectively, minimizing downtime and maximizing productivity.

In addition, we provide training and education programs to help you and your team get the most out of your Vacuum Brazing Machine. Our experts will teach you the best practices for operation, maintenance, and safety to ensure that your machine is performing at its highest level.

Packing and Shipping:

Product Packaging:

The vacuum brazing machine will be packaged in a wooden crate to ensure safe transportation. The crate will be lined with foam padding to prevent any damage during shipping. The machine will be securely fastened to the bottom of the crate to prevent it from moving around during transit.

Product Shipping:

The vacuum brazing machine will be shipped via a reputable courier service to ensure timely and safe delivery. The shipping cost will be calculated based on the destination and weight of the crate. The customer will receive a tracking number to monitor the shipment's progress. It is recommended that the customer inspect the crate upon arrival to ensure that there is no damage during shipping.