-

StevenCHN-TOP offer very good service and the products help us a lot

StevenCHN-TOP offer very good service and the products help us a lot -

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines -

MikeBest products with best price, CHN-TOP well done!

MikeBest products with best price, CHN-TOP well done!

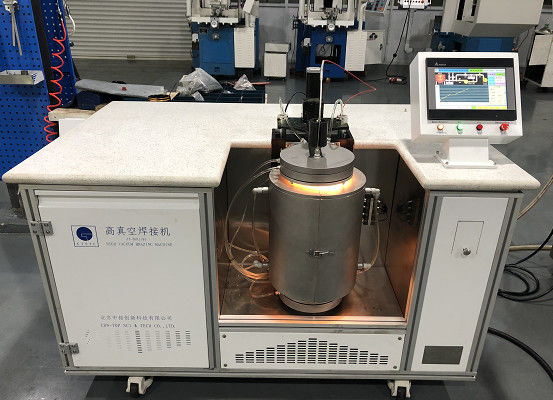

180*500mm Chamber Automatic Vacuum Brazing Machine For High Temperature Brazing

| Brazing Capability | CNGA1204 Appr. 600pcs/cycle | Max Vacuum Rate | 10^-2 Pa |

|---|---|---|---|

| Chamber | Quartz Glass Tube | Vacuum Process | 1.Cleaning,2. Fixiing Flux,3.Drying At The Temperature Of 200℃ For 30mins,4.Brazing |

| Dimensions | L1600×W950×H900mm | Machine Type | Vacuum Welding/Brazing Machine |

| Power Supply | 380V-3Phases-5Wires/20KW | Operation Mode | Automatic |

| Highlight | Automatic Vacuum Brazing Machine,Automatic Furnace Brazing Machine,PCBN Inserts Electric Brazing Machine |

||

180*500mm Chamber Size Automatic Vacuum Brazing Machine For High Temperature Brazing

Product Description:

The Vacuum Brazing Machine is a high temperature vacuum welder designed for ultra hard materials such as PCD (polycrystalline diamond) and PCBN (polycrystalline cubic boron nitride) inserts. It is equipped with advanced features to ensure precise and efficient brazing of these materials.

The Vacuum Brazing Machine performs a 4-step vacuum process to achieve superior results:

- Cleaning: The first step of the process involves thorough cleaning of the materials to be brazed. This ensures a clean surface for a strong and stable bond.

- Fixing Flux: Next, the machine applies a special flux that helps to fix the materials in place during the brazing process.

- Drying: The materials are then dried in the vacuum chamber at a temperature of 200℃ for 30 minutes. This helps to eliminate any residual moisture and prepare the materials for brazing.

- Brazing: The final step is the actual brazing process, which takes place in the vacuum chamber. The high temperature and pressure created in the chamber ensure a strong and precise bond between the materials.

The Vacuum Brazing Machine has a chamber size of 180*500mm, providing enough space for multiple inserts to be brazed at once. This allows for increased productivity and efficiency.

To maintain the high temperature required for brazing, the machine is equipped with a water cooling system. This helps to prevent overheating and ensures consistent and accurate brazing results.

The Vacuum Brazing Machine requires a power supply of 380V-3Phases-5Wires and has a power capacity of 20KW. This ensures stable and reliable operation for long periods of time.

The Vacuum Brazing Machine is specifically designed for brazing PCD and PCBN inserts, which are commonly used in the cutting and drilling of ultra hard materials. It is suitable for a wide range of industries including aerospace, automotive, and medical.

With its advanced vacuum process, large chamber size, and efficient cooling system, the Vacuum Brazing Machine is the ideal solution for achieving strong and precise bonds in PCD and PCBN inserts. Its reliability and versatility make it a valuable asset for any manufacturing process.

Keywords: Diamond Vacuum Brazing Device, High Temperature Vacuum Welder, Vacuum Brazing System for Ultra hard Materials, PCD/PCBN Inserts Brazing, Flux Fixing, Water Cooling

Features:

- Product Name: Vacuum Brazing Machine

- Application: PCD/PCBN Inserts Brazing

- Max Vacuum Rate: 10^-2 Pa

- Operation Mode: Automatic

- Weight: 600kg

- Heating Source: 18pcs Halogen Tubes

- Key Features:

- Diamond Vacuum Brazing Device

- Vacuum Soldering Equipment

- Diamond Tool Brazing Machine

Technical Parameters:

| Product Name: | Vacuum Brazing Machine |

|---|---|

| Product Type: | Tungsten Carbide Vacuum Brazing Machine |

| Vacuum Process: | 1. Cleaning 2. Fixing Flux 3. Drying At The Temperature Of 200℃ For 30mins 4. Brazing |

| Weight: | 600kg |

| Chamber: | Quartz Glass Tube |

| Power Supply: | 380V-3Phases-5Wires/20KW |

| Brazing Capability: | CNGA1204 Appr. 600pcs/cycle |

| Chamber Size: | 180*500mm |

| Max Vacuum Rate: | 10^-2 Pa |

| Chilling: | Water Cooling |

| Application: | PCD/PCBN Inserts Brazing |

| Machine Type: | Vacuum Welding/Brazing Machine |

Applications:

Brand Name: CTSTC

Model Number: ZT-ZHKJ180

Place of Origin: CHINA

Certification: CE

Minimum Order Quantity: 1

Price: Negotiable

Packaging Details: plywood box

Delivery Time: 45-60 days

Payment Terms: TT/LC/Western Union

Dimensions: L1600×W950×H900mm

Chilling: Water Cooling

Heating Source: 18pcs Halogen Tubes

Guarranty: 1 Year

Power Supply: 380V-3Phases-5Wires/20KW

The Vacuum Brazing Machine-CTSTC is a state-of-the-art automatic vacuum machine designed specifically for PCD/PCBN materials. It is a vacuum brazing device that provides a reliable and efficient way to join ultra hard materials together, such as diamond, cubic boron nitride and other advanced ceramics.

The Vacuum Brazing Machine-CTSTC is perfect for use in industries that require high precision and strength in their materials, such as aerospace, automotive, electronics, and medical equipment manufacturing. It can also be used for research and development purposes in universities and laboratories.

- Automatic vacuum machine designed for PCD/PCBN materials

- Provides a reliable and efficient way to join ultra hard materials together

- Water cooling system for efficient heat dissipation

- 18pcs Halogen tubes as heating source

- Guaranteed quality with 1 year warranty

- Power supply of 380V-3Phases-5Wires/20KW for stable operation

In a high-tech manufacturing plant, the Vacuum Brazing Machine-CTSTC is used to join PCD/PCBN materials together for the production of precision cutting tools. The machine is operated by skilled technicians who carefully place the materials in the vacuum chamber and set the heating temperature according to the specific requirements. As the machine heats up, the materials are brazed together with precision and accuracy under the vacuum environment. The water cooling system ensures that the materials cool down quickly, resulting in a strong and durable bond. The finished products are then inspected and tested for quality before being shipped to customers.

The Vacuum Brazing Machine-CTSTC is a cutting-edge product that showcases the advanced technology and expertise of CTSTC. With its automatic operation, water cooling system, and reliable heating source, it is the perfect solution for joining ultra hard materials together. Its application in various industries and research fields makes it a versatile and valuable machine to have. With a guaranteed quality and efficient production process, the Vacuum Brazing Machine-CTSTC is definitely a top choice for businesses and institutions looking for the best in vacuum brazing systems.

Customization:

Brand Name: CTSTC

Model Number: ZT-ZHKJ180

Place of Origin: CHINA

Certification: CE

Minimum Order Quantity: 1

Price: Negotiable

Packaging Details: Plywood box

Delivery Time: 45-60 days

Payment Terms: TT/LC/Western Union

The CTSTC Vacuum Brazing Machine is the perfect solution for all your PCD/PCBN tools vacuum brazing needs. This high temperature vacuum welder is designed to provide efficient and reliable vacuum soldering for your tools. With our customizable service, you can be sure to get a machine that meets all your specific requirements.

- Chamber: Quartz Glass Tube

- Dimensions: L1600×W950×H900mm

- Guarantee: 1 Year

- Heating Source: 18pcs Halogen Tubes

- Maximum Vacuum Rate: 10^-2 Pa

Our Vacuum Brazing Machine can be tailored to meet your specific needs and preferences. We offer a wide range of customization options including:

- Chamber size and material

- Heating source type and quantity

- Vacuum rate requirements

- Control system and software

- Additional features and functions

Contact us now to discuss your customization requirements and get a quote for your customized Vacuum Brazing Machine.

Keywords: PCD/PCBN Tools Vacuum Brazing Machine, High Temperature Vacuum Welder, Vacuum Soldering Equipment

Support and Services:

Our Vacuum Brazing Machine is a cutting-edge product designed to meet the demands of various industries. As a pioneer in the field of vacuum brazing technology, we are committed to providing top-notch technical support and services to ensure the smooth operation and maintenance of our machine.

Our team of highly skilled and experienced engineers is dedicated to providing comprehensive technical support to our customers. We offer remote assistance, on-site visits, and training sessions to help you understand the features and functions of our Vacuum Brazing Machine.

In case of any technical issues, our experts are available 24/7 to provide prompt solutions and minimize downtime. We also offer regular maintenance services to keep your machine in optimal condition and prolong its lifespan.

We understand the importance of proper training and education in utilizing our Vacuum Brazing Machine to its full potential. That's why we provide in-depth training programs and educational resources to our customers.

Our training programs cover topics such as machine operation, maintenance, troubleshooting, and safety precautions. We also offer customized training sessions to meet the specific needs of your business.

To ensure the continuous and efficient operation of your Vacuum Brazing Machine, we offer a wide range of high-quality spare parts. Our spare parts are manufactured using the latest technology and are designed to fit seamlessly with our machine.

In addition, we also provide upgrades for our Vacuum Brazing Machine to keep it up-to-date with the latest technological advancements. Our team will assist you in selecting the best upgrades for your machine based on your specific requirements.

At Vacuum Brazing Machine, customer satisfaction is our top priority. We have a dedicated customer service team that is always ready to assist you with any inquiries or concerns you may have.

Our team is available via phone, email, or online chat to provide you with prompt and efficient support. We value your feedback and continuously strive to improve our products and services to meet your evolving needs.

With our comprehensive technical support and services, you can rely on our Vacuum Brazing Machine to deliver exceptional performance and quality results for your business. Get in touch with us today to learn more about our product and services.