-

StevenCHN-TOP offer very good service and the products help us a lot

StevenCHN-TOP offer very good service and the products help us a lot -

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines -

MikeBest products with best price, CHN-TOP well done!

MikeBest products with best price, CHN-TOP well done!

High Temperature PCBN Tools Vacuum Brazing Service Anti Corrosive

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Vacuum Brazing Service For PCD/PCBN | Brazing Type | Vacuum Brazing |

|---|---|---|---|

| Brazing Circle Time | Less Than 90min | Brazing Quantity | More Than 500 Pcs Per Circle |

| Highlight | High Temperature Vacuum Brazing Service,PCBN Tools Vacuum Brazing Service |

||

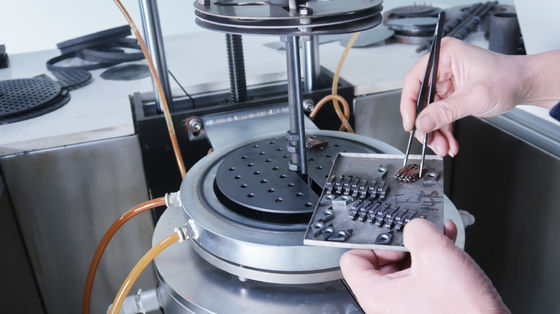

PCBN Tools Vacuum Brazing Service Cutting Tools 800 Degree High Temperature

Product Advantages

1. Clean-free, no oxide layer, environmentally friendly.

2. High brazing strength, no weld flaw

3. High precision, even very small and complex workpiece can be brazed.

4. More stable, nice anti-corrosive quality.

5. High efficiency, lower cost.

Description:

Our company provide one step processing service for ultra-hard cutting tools, including laser cutting, carbide inserts notching, vacuum brazing, chip breaker processing and so on.

Vacuum brazing is an efficient way to achieve a finished joint.

It can cost effectively join complex parts–even nonmetals and dissimilar metals. Because the temperature does not reach the melting point of the base metals being joined, there are a great variety of materials that can be joined by the brazing process–including ferrous and nonferrous metals and even ceramics.

| Brazing equipment | ZT-ZKHJ280 |

| Brazing Type | Vacuum brazing |

| Material | PCD/PCBN/Carbide Inserts |

| Brazing Circle Time | ≦90min |

| Brazing Quality/ | ≥500pcs(per machine) |

Example

| Material | SB95S2(Ijin PCBN)/CNGA120404 |

| Size | 80°T 8.34*4.61mm/80°12.9(D)*4.76(S)*0.4R*5.16(D1) |

| Tolerances | 0.025mm |

| Processing time | At most 1day |

Our process procedure

![]()

1. Design drawing according to requirements of clients.

2. Carbide inserts notching

3. Cleaning and apply solder paste

4. Drying

5. Vacuum brazing

6. Quality testing

7. Shipping or moving on to next procedure.