-

StevenCHN-TOP offer very good service and the products help us a lot

StevenCHN-TOP offer very good service and the products help us a lot -

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines -

MikeBest products with best price, CHN-TOP well done!

MikeBest products with best price, CHN-TOP well done!

Vacuum Brazing PCBN Cutting Tools High Efficiency 800 Degree

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Vacuum Brazing Service For PCD/PCBN | Brazing Type | Vacuum Brazing |

|---|---|---|---|

| Brazing Circle Time | Less Than 90min | Brazing Quantity | More Than 500 Pcs Per Circle |

| Highlight | 800 degree PCBN Cutting Tools,Vacuum Brazing PCBN Cutting Tools |

||

PCBN Inserts Tools Vacuum Brazing Service Cutting Tools 800 degree

Product Advantages

1.Competitive price, high quality.

2. High efficiency

3. Environmentally friendly.

4. Have good safety production conditions

5. Furnace internal structure and fixture life is longer

Description:

Our company provide one step processing service for ultra-hard cutting tools, including laser cutting, carbide inserts notching, vacuum brazing, chip breaker processing and so on.

| Brazing equipment | ZT-ZKHJ280 |

| Brazing Type | Vacuum brazing |

| Material | PCD/PCBN/Carbide Inserts |

| Brazing Circle Time | ≦90min |

| Brazing Quality/ | ≥500pcs(per machine) |

Example

| Material | SB95S2(Ijin PCBN)/CNGA120404 |

| Size | 80°T 8.34*4.61mm/80°12.9(D)*4.76(S)*0.4R*5.16(D1) |

| Tolerances | 0.025mm |

| Processing time | At most 1day |

Our process procedure

![]()

1. Design drawing according to requirements of clients.

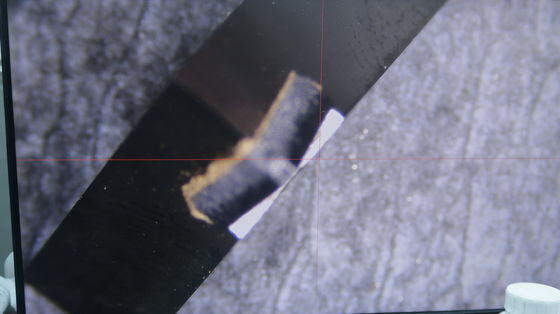

2. Carbide inserts notching

3. Cleaning and apply solder paste

4. Drying

5. Vacuum brazing

6. Quality testing

7. Shipping or moving on to next procedure.