-

StevenCHN-TOP offer very good service and the products help us a lot

StevenCHN-TOP offer very good service and the products help us a lot -

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines -

MikeBest products with best price, CHN-TOP well done!

MikeBest products with best price, CHN-TOP well done!

High Precision PCBN PCD Grinding Machine With 0.05mm Tool Tip Arc Radius

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Guarranty | 2 Years | After-sales Service | On-line Training |

|---|---|---|---|

| Payment | T/T, M/T, D/D, L/C | Minimum Order | 1 Set |

| Application | PCD/PCBN | Product Name | High Precision PCD/PCBN Tools Grinder Supplied By Chinese Manufacturer |

| Key Word | PCD/PCBN Grinder | Packing Size | 1850*2100*1650mm |

| Highlight | 0.05mm PCD Grinding Machine,5 Axis PCD Grinding Machine,CE PCBN PCD Grinding Machine |

||

High Precision PCD/PCBN Tools Grinder Supplied by Chinese Manufacturer

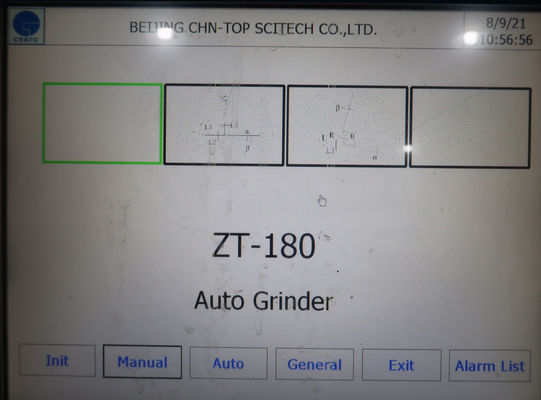

ZT-180 Type CNC Grinder is mainly used for grinding multiple cutters and parts such as artificial diamond, cubic boron nitride and hard alloy etc. The machine tool has sufficient rigidity and precision, which can realize constant pressure grinding and satisfy the grinding of high-precision and high-finish cutters to obtain the good grinding result.

![]()

Design Features:

ZT-180 is a high precision PCD&PCBN indexable inserts automatic grinder. Fully-automatic closed loop machining in grinding process, on-line inspection, stable, efficient and precise. The machine tool body and the main castings were naturally aged for an average of 18 months.

It adopts Swiss original SCHNEEBERGER high-load rolling needle linear guideway which is precise, durable and durable.

Use advanced technical CNC control system, 5 axis control, two –axis CNC machining, Automatic, closed loop control during grinding.

All servo motors adopt Japanese YASKAWA servo motor.

Vertical axis reducer adopts Japanese HARMONIC reducer with almost zero clearance.

The spindle motor adopts Taiwan brushless motor, which is firm and durable.

Equipped with high precision, high sensitive measuring head, the realization of on-line measurement.

Linear grating and angle encoder of this model is FAGOR, make sure the precision indication.

The whole pneumatic system use JAPAN SMC brand, to get rapid feed and infeed.

Worktable can rotate within 270 degrees and the position can adjust. Full-closed loop control, Make sure precision and coherence.

Camera with LCD monitor and precision scale for easy set up& inspection during grinding.

The optical system is equipped with a high-definition original camera, Precision of arc radius of tool tip 0.05mm, Online observation and monitoring are implemented.

The numerical control system adopts GOOGOL technology system, and the software is the program software specially developed for PCD&PCBN blade grinding.

Equipped with electronic handle, it is convenient to adjust the position of each machining axis and realize manual grinding.

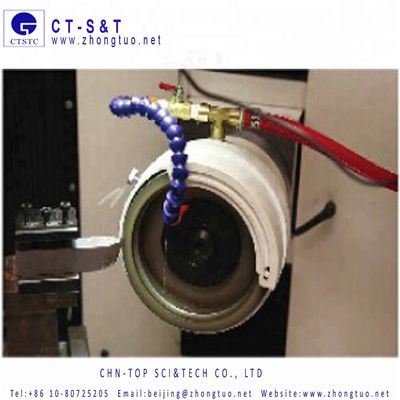

Fully enclosed enclosure, equipped with oil mist recovery device, effectively avoid oil mist damage to human body and environmental pollution.

Reduce the damage caused to electronic components due to overheating or over-cooling, fully enclosed structure, effective anti-oil mist, etc., ensure more stable and efficient operation of electrical accessories

![]()

![]()

![]()

Technical Parameters

| Tip Radius | Unlimited |

| Grinding Pressure | 0-450N (adjustable) |

| Spindle Speed | 0-4200RPM (adjustable) |

| Grinding Wheel Size | 150*40*40mm (D*H*T) |

| Grinding Wheel Oscillation Frequency | 0-45/min (adjustable) |

| Grinding Wheel Oscillation Distance | 0-40mm (adjustable) |

| Grinding Wheel Height Adjustment | 140mm |

| Grinding Wheel Traveling Range | 400mm |

| Grinding Wheel Inclination | -13°~+24° |

| Cross Table Swiveling Angle | 270° |

| Size of Cross Table | 210mm*160mm with 4T grooves |

| Readout of Linear Gratings | 0.001mm |

| Spindle Power | 2.2kW |

| Dimension | 1850*2100*1650mm (L*H*W) |

| Net Weight | 2080kgs |