-

StevenCHN-TOP offer very good service and the products help us a lot

StevenCHN-TOP offer very good service and the products help us a lot -

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines -

MikeBest products with best price, CHN-TOP well done!

MikeBest products with best price, CHN-TOP well done!

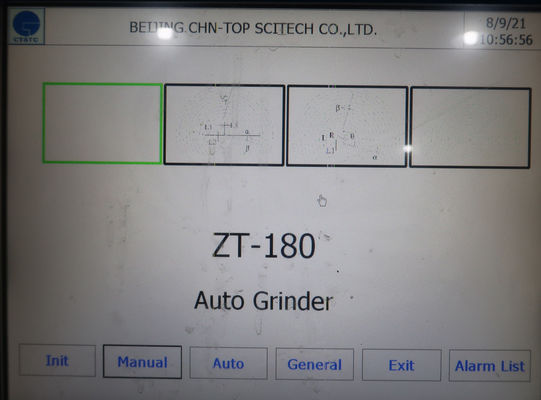

4200RPM Spindle Speed CNC Automatic Grinding Machines For PCD / PCBN Tools

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Delivery Time | 45-60days After Pre-payment | After-sales Service | Online-service |

|---|---|---|---|

| Payment | T/T, M/T, D/D, L/C | Minimum Order | 1 Set |

| Application | For PCD/PCBN Grinding | Product Name | High Precision Automatic Grinder For PCD / PCBN Tools |

| Key Word | PCD/PCBN Grinder | Packing Size | 1850*2100*1650mm |

| Highlight | 4200RPM Automatic Grinding Machines,PCBN CNC Automatic Grinding Machines,PCD Automatic Grinding Machines |

||

High Precision Automatic Grinder For PCD / PCBN Tools

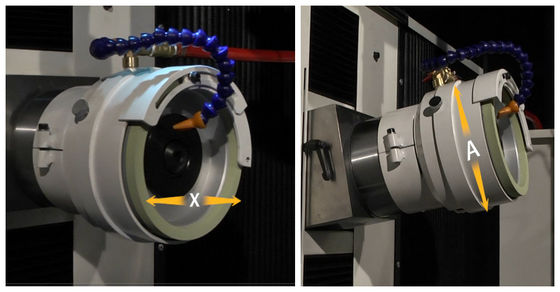

ZT-180 Type CNC Grinder is mainly used for grinding multiple cutters and parts such as artificial diamond, cubic boron nitride and hard alloy etc. The machine tool has sufficient rigidity and precision, which can realize constant pressure grinding and satisfy the grinding of high-precision and high-finish cutters to obtain the good grinding result.

ZT-180 is a high precision PCD&PCBN indexable inserts automatic grinder. Fully-automatic closed loop machining in grinding process, on-line inspection, stable, efficient and precise. The machine tool body and the main castings were naturally aged for an average of 18 months.

![]()

Design Features:

• Extremely rigid construction with heavy duty cast iron body, more than 18 months natural

ageing, stable and durable.

• SCHNEEBERGER heavy duty and precision linear slide guide for its accuracy and long life

• Vertical axis reducer adopts high precision reducer, almost zero clearance.

• 5-axis CNC and 4-axis linkage, the whole grinding process is fully automatic and

closed-loop control

• Linear grating and angle encoder are FAGOR products, ensure measurement accuracy.

• Equipped with high precision and high sens巾vity probe to realize on-line measurement.

• The main servo motor is of Yaskawa servo motor.

• Feed shaft adopts a linear motor, with good rig心ty, high precision and fast reaction.

• Spindle motor is of Taiwan brushless motor, stable and durable. Electric spindle can also be

optional.

• Two sets of grinding wheel dressers, one is responsible for grinding wheel leveling, the other

is responsible for cleaning the surface of grinding wheel on line

• Equipped with electronic handwheel, can easily ad」ust the position of each machining shaft

and achieve manual grinding.

![]()

![]()

Technical Parameters

| Tip Radius | Unlimited |

| Grinding Pressure | 0-450N (adjustable) |

| Spindle Speed | 0-4200RPM (adjustable) |

| Grinding Wheel Size | 150*40*40mm (D*H*T) |

| Grinding Wheel Oscillation Frequency | 0-45/min (adjustable) |

| Grinding Wheel Oscillation Distance | 0-40mm (adjustable) |

| Grinding Wheel Height Adjustment | 140mm |

| Grinding Wheel Traveling Range | 400mm |

| Grinding Wheel Inclination | -13°~+24° |

| Cross Table Swiveling Angle | 270° |

| Size of Cross Table | 210mm*160mm with 4T grooves |

| Readout of Linear Gratings | 0.001mm |

| Spindle Power | 2.2kW |

| Dimension | 1850*2100*1650mm (L*H*W) |

| Net Weight | 2080kgs |

Attention:

1.When inject the oil into the tank, press the upper limit position indicator to avoid excessive injection.

2.Use the fresh oil. (Kerosene, gasoline, water and other liquids are prohibitive.)

3.Don’t use the mix oil for the different grades, otherwise the precipitate will be produced, mechanical failure will be occurred.

4.The broken inlet filter or removed will bring the dirt into the tank, mechanical failure will happen during the operation.

5.Lubrication pump use the rubber and plastic products, or other non-metallic material, don’t use the corrosive oil to prevent corrosion damage.

6.Keep the same power supply with the product description.

7.Make sure the worm is running after turning on the power supply.

8.In order to exclude the air and dust in the tube, pull the handle limit wheel and fill-in all the lubricant after the piping system matching.

9.Without oil in the tank, mechanical failure will happen after the long idling, and make the parts broken.

10.Must be grounded during installation.

11.Don’t push the limit wheel handle from the top to down.

12.Maintenace is available for the regular work.