-

StevenCHN-TOP offer very good service and the products help us a lot

StevenCHN-TOP offer very good service and the products help us a lot -

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines -

MikeBest products with best price, CHN-TOP well done!

MikeBest products with best price, CHN-TOP well done!

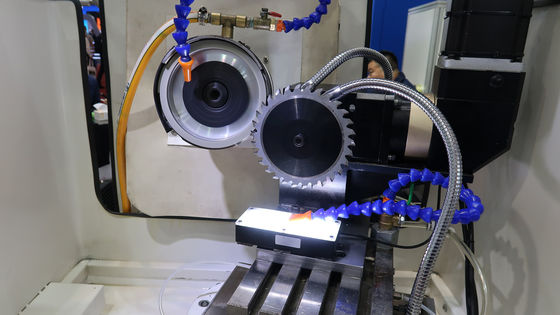

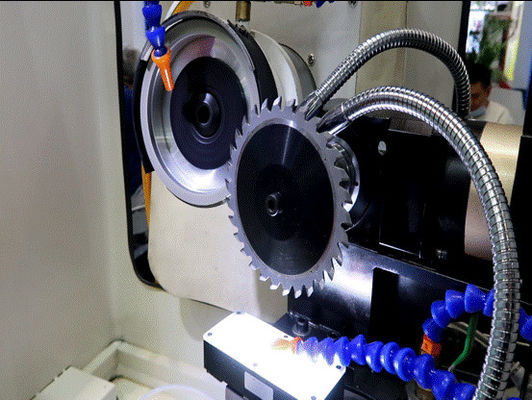

V Cut Diamond Tools PCD Grinder Machine Automatic For Saw Blade

| Type | CNC | Model No. | ZT-90V |

|---|---|---|---|

| Brand | CHN-TOP | Application | V Cut Diamond Blade, PCD Blade And Other Saw Blade |

| Highlight | PCD Grinder Machine,V Cut Diamond pcd grinder,PCD automatic grinder machine |

||

| Radius Tip | 0-70mm | |

|---|---|---|

| Grinding pressure | 0-450N Adjustable | |

| Spindle speed | 0-4200RPM adjustable | |

| Grinding wheel size | 150*40*40mm (D*H*T) | |

| Grinding wheel oscillation frequency | 0-45/min adjustable | |

| Grinding wheel oscillation distance | 0-70mm adjustable | |

| Grinding wheel height adjustment | 140mm | |

| Image system resolutionnge | 1280*960 | |

| Image system pixel | 3.75μm*3.75μm | |

| Optical lens object distance | 300mm | |

| Magnification | 45-250 times | |

| CNC division axis resolution | 8arcmin | |

| CNC Y axis resolution | 0.01° |

PCD GRINDING MACHINE FOR SAW BLADE V CUT DIAMOND TOOLS PCBN TOOLS WITH PRECISION LINEAR SLIDE CNC CONTROL SYSTEM

ZT-90CNC/V Grinding Machine for Blade Tools

![]()

Features

-

1.All cast machine body and cast accessories are average 24 months natural ageing which it’s high rigidity and stability.

2. Grinding head is a up-down spindle and angle adjustable, featuring in high running speed high precision.

3. Pneumatic systems imported from SMC of Japan , fast infeed and out feed worktable with flexible grinding .

4. All of the CNC control system is self -R&D software, embedded CCD and measurement system, all the sensors, servo control are closed control system to make sure it’s accuracy and stability.

5. Use a new visual Technology, online measurements, auto grinding at the whole process.

And parameters auto memory , error code alarm, more productivity and efficient.

6. Only one time fitting, then grinding by auto from first to last tip with higher efficient and consistency

7. Machine with a high precision CNC division flange, Precision recognition .

TECHNICAL PARAMETERS

ZT-90V Grinder is a special equipment which focus on grinding diamond V-Cut tools and some saw blades. It’s also can grind carbide tools also. This models is improved on original ZT-90 diamond grinding machine with CNC control axis.

One time fitting can finish grinding work by automatically which it’s high precision. Auto infeed and out feed, automatically scale division and measurements. The software support parameter setting record and can turn to next tip by automatic also .

It’s error code recognize by software. This model is widely used for PCB board V-Cut tool, wooden blades and other diamond or carbide tools of this kind

ZT-90CNC/V Prameter Specification

|

Image system resolution |

1280*960 |

|

Image system pixel |

3.75μm*3.75μm |

|

Optical lens object distance |

300mm |

|

Magnification |

45-250 times |

|

CNC division axis resolution |

8arcmin |

|

CNC infeed axis resolution |

0.001mm |

|

CNC Y axis resolution |

0.01° |

|

Grinding pressure |

0-450N(Adjustable) |

|

Grinding wheel speed |

0-4200RPM(50HZ) |

|

Grinding wheel size |

125D×40H×40T |

|

Grinding wheel oscillation frequency |

0-45/min(Adjustable) |

|

Grinding wheel oscillation distance |

0-40mm(Adjustable) |

|

Grinding wheel height adjustment |

140mm |

|

Grinding wheel traveling range |

170mm |

|

Grinding wheel inclination |

-13°—+24° |

|

Cross table swiveling angle |

0-270° |

|

Readout of linear gratings |

0.001mm |

|

Spindle power |

2.2KW |

|

Machine Size |

1200(L) ×1168(H) ×1530(W)mm |

Working Table

![]()

Grinding Samples

![]()

![]()

Factory View

![]()

![]()

![]()

CHN-TOP is the company offer comprehensive solutions for diamond tools making

![]()

![]()

FAQ

Q: Are you trading company or manufacturer ?

A: We are manufactory for PCD,CBN diamond tools equipments and service, we have our own R&D

team and production workshop. We can develop our customers' unique products according to their needs.

Q: How long is your delivery time?

A: Generally it is 2-3 days for CNC diamonds tools machining, and 45-60 days for machines.

Q: How about your after-sales system?

A: We have a comprehensive after-sales system, which can provide one-on-one online video service

according to the needs of customers, and one-on-one service to solve customers' worries.

Q: How about your delivery date for PCD/PCBN blank?

A: 1), PCD/PCBN Blank, we have signed a Chinese agency agreement with international big brands,

customers do not need to worry about genuine and delivery problems;

2), We can provide a wide range of products with PCD/ PCBN Blank, customers can choose goods according

to different needs, we also have self-developed domestic PCD with high quality, the price is very competitive.

Q: How about the cutting thickness and width of Laser cutting machine?

A: 1), Cutting thickness, single-sided cutting maximum thickness of 4-5mm, double-sided cutting maximum

thickness of 8 10mm.

2), Slit width: 0.05-0.15mm, accuracy can reach 0.01mm.

![]()