-

StevenCHN-TOP offer very good service and the products help us a lot

StevenCHN-TOP offer very good service and the products help us a lot -

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines -

MikeBest products with best price, CHN-TOP well done!

MikeBest products with best price, CHN-TOP well done!

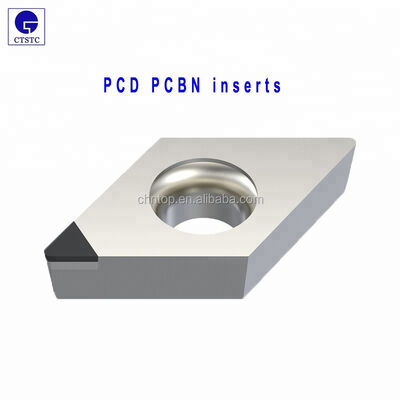

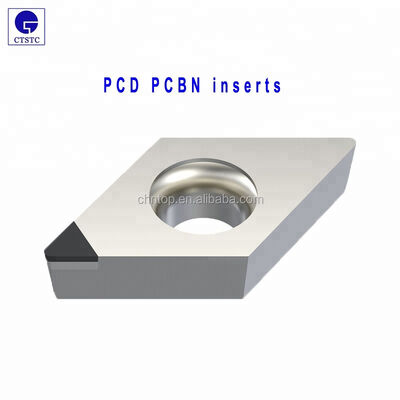

DHL Transportation PCD TOOLS Providing Smooth Surfacefinish Optimized for Material Removal and Consistent Machining Results

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Diamond Thickness | 0.5-08mm | Grainsize | Fine To Coarse |

|---|---|---|---|

| Size | 62mm | Granularity | 6um |

| Thinckness | 1.0mm/1.2mm/1.6mm/2.0mm/3.2mm | Compatibility | Suitable For Various Machines |

| Productname | PCD Blank | Transportation | DHL, UPS, TNT, FEDEX |

| Highlight | PCD blank for material removal,DHL transportation PCD tools,PCD blank smooth surface finish |

||

Product Description:

The PCD Blank is an essential component designed for use in a wide range of industrial applications, especially where precision and durability are paramount. Engineered with high-quality materials, this product stands out in the market due to its exceptional attributes, making it a preferred choice for professionals seeking reliable and efficient solutions. The PCD Blank is particularly known for its compatibility, making it suitable for various machines, which enhances its versatility and usability across different sectors.

One of the key features of the PCD Blank is its compatibility. It is meticulously crafted to fit seamlessly with a variety of machines, ensuring that it can be integrated into existing setups without the need for extensive modifications. This adaptability makes it an invaluable asset for businesses that operate multiple types of equipment or need to switch between different tools frequently. The ability to work with diverse machinery not only saves time but also reduces costs associated with purchasing multiple specialized components.

In terms of performance, the PCD Blank exhibits low conductivity, which is a significant advantage in many industrial processes. Low conductivity helps in minimizing heat transfer and electrical interference, thereby enhancing the safety and efficiency of operations. This characteristic is especially beneficial when the PCD Blank is used in conjunction with PCD tools, as it helps maintain the integrity and longevity of both the blank and the tools themselves.

Transparency is another standout attribute of the PCD Blank. With high transparency, this product allows for precise inspection and quality control during manufacturing and assembly processes. High transparency facilitates better visual monitoring, which is crucial for ensuring that the PCD Blank meets stringent industry standards. This feature also aids in reducing errors and improving the overall quality of the finished products that incorporate the PCD Blank.

The surface finish of the PCD Blank is smooth, contributing to its superior performance and aesthetic appeal. A smooth surface finish not only enhances the physical appearance of the product but also plays a critical role in reducing friction and wear when the blank is used with PCD discs and other PCD tools. This smoothness ensures that the PCD Blank operates efficiently, with minimal resistance and prolonged service life, thereby delivering excellent value for investment.

PCD discs are widely recognized for their hardness and durability, and the PCD Blank serves as a critical foundation in the manufacturing and application of these discs. By providing a high-quality blank with excellent transparency, low conductivity, and a smooth surface finish, manufacturers can produce PCD discs that meet the highest standards of precision and reliability. The PCD Blank’s compatibility with various machines further streamlines production processes, allowing for greater flexibility and efficiency.

Moreover, the PCD Blank is an integral part of the broader category of PCD tools, which are renowned for their cutting-edge technology and superior performance in demanding industrial environments. Whether used in cutting, grinding, or drilling applications, the PCD Blank ensures that PCD tools perform optimally, delivering consistent results and enhancing productivity. Its unique combination of attributes supports the development of advanced PCD tools that cater to specific industrial needs.

In summary, the PCD Blank is a versatile, high-performance product that offers significant advantages in terms of compatibility, conductivity, transparency, and surface finish. Its smooth surface and low conductivity make it ideal for use with PCD discs and PCD tools, ensuring efficient and reliable operation. Suitable for various machines, the PCD Blank is a dependable choice for industries seeking durable, high-quality components that enhance the performance and longevity of their equipment. Investing in the PCD Blank means choosing a product that delivers excellent quality, adaptability, and efficiency, making it an indispensable part of the PCD tools and PCD disc manufacturing process.

Features:

- Product Name: PCD Blank

- Surface Finish: Smooth

- Thickness Options: 1.0mm, 1.2mm, 1.6mm, 2.0mm, 3.2mm

- Transportation Methods: DHL, UPS, TNT, FEDEX

- Conductivity: Low

- Grain Size: Fine to Coarse

- Made from high-quality POLYCRYSTALLINE DIAMOND material

- Ideal for manufacturing PCD DISC products

- Ensures durability and precision for PCD DISC applications

Applications:

The CTSTC PCD Blank, model number 1.6-10W, is an exceptional product designed for a wide range of industrial applications where precision and durability are paramount. As a premium polycrystalline diamond (PCD) tool, it boasts a round shape with a diamond thickness ranging from 0.5 to 0.8mm, and a granularity of 6um, ensuring superior cutting and grinding performance. The surface finish is smooth, contributing to enhanced efficiency and longevity in various machining and manufacturing processes.

PCD tools like the CTSTC PCD Blank are extensively used in industries such as automotive, aerospace, woodworking, and electronics, where high hardness and wear resistance are critical. With a hardness of up to 8000 HV, this product can withstand intense abrasion and high-speed operations, making it ideal for cutting, drilling, and shaping hard materials like non-ferrous metals, composites, and ceramics. Its robust characteristics enable manufacturers to achieve higher precision and improved surface quality, reducing downtime and operational costs.

Thanks to CTSTC’s reliable supply ability of 1000 pieces per day and a minimum order quantity of just one unit, businesses can easily procure this PCD tool for both small-scale projects and large production runs. The product is conveniently packaged in a plastic box to ensure safe handling and storage. With a delivery time of 5 to 10 days and flexible payment terms including TT, LC, and Western Union, customers enjoy a seamless purchasing experience tailored to their needs.

Typical application occasions for the CTSTC PCD Blank include precision machining of complex components, high-performance cutting in CNC machines, and finishing operations in mold making and die manufacturing. Its smooth surface finish and consistent granularity allow it to be used in scenarios where minimal material deformation and high accuracy are required. This makes it a trusted choice for manufacturers looking to enhance productivity and maintain superior product quality.

In summary, the CTSTC 1.6-10W PCD Blank is a versatile and high-performance polycrystalline diamond tool designed to meet the demanding requirements of modern manufacturing. Whether used for cutting, shaping, or finishing, it delivers outstanding hardness, precision, and durability. Its availability with negotiable pricing and efficient delivery further supports various industrial needs, making it an essential component in the portfolio of PCD tools.

Packing and Shipping:

Each PCD Blank product is carefully packaged to ensure maximum protection during transit. The product is securely placed in a custom-fitted protective case, which is then cushioned with foam padding to prevent any movement or damage.

The packaged product is then enclosed in a sturdy, corrugated cardboard box designed to withstand shipping pressures and impacts. The box is sealed with strong adhesive tape and clearly labeled with handling instructions and product information.

For shipping, we use reliable courier services that provide tracking and insurance options. We ensure timely dispatch and delivery, maintaining the product's integrity from our facility to your doorstep.