-

StevenCHN-TOP offer very good service and the products help us a lot

StevenCHN-TOP offer very good service and the products help us a lot -

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines -

MikeBest products with best price, CHN-TOP well done!

MikeBest products with best price, CHN-TOP well done!

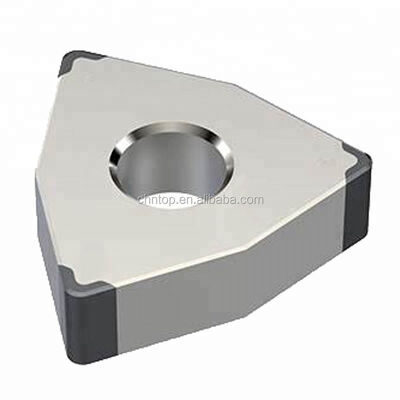

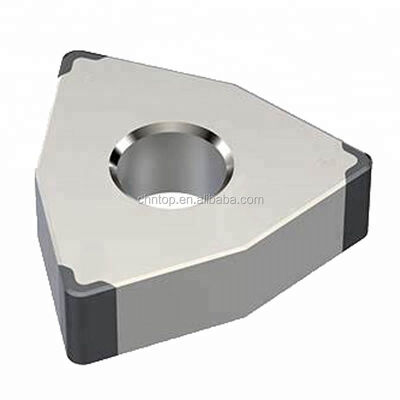

1 Year Guarranty PCD Blank Inserts Ideal for Metalworking and Precision Cutting Applications in Manufacturing

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Operatingtemperature | Up To 700°C | Diamond Thickness | 0.5-08mm |

|---|---|---|---|

| Size | Customizable Dimensions | Wearresistance | Superior |

| Toughness | Middle | Total Thickness | 1.0mm/1.6mm/2.0mm/3.2mm |

| Productname | PCD Blank | Model | 2.0-CMW |

| Highlight | PCD blank inserts for metalworking,PCD blank with 1 year warranty,precision cutting PCD blank inserts |

||

Product Description:

The PCD Blank model 2.0-CMW represents a pinnacle of innovation and durability in the realm of cutting tools, particularly designed for applications requiring exceptional wear resistance and precision. As an essential component in the manufacturing of PCD tools, this PCD Blank offers superior performance that meets the rigorous demands of modern machining and cutting operations.

One of the standout features of the 2.0-CMW PCD Blank is its superior wear resistance. Engineered to withstand the harshest conditions, this product ensures prolonged tool life and consistent cutting quality. This exceptional wear resistance translates to fewer tool changes, reduced downtime, and ultimately, increased productivity. Whether used in high-speed machining or abrasive environments, the PCD Blank maintains its integrity and sharpness, making it an invaluable asset in industrial applications.

The PCD Blank is available with two distinct bond types: metal bond and resin bond. This versatility allows manufacturers and users to select the optimal bonding method based on their specific machining requirements. Metal bond PCD blanks are known for their robustness and ability to handle heavy-duty cutting tasks, while resin bond variants offer enhanced precision and finer finishes. This flexibility ensures that the PCD Blank can cater to a wide range of cutting scenarios, making it a preferred choice for producing high-quality PCD inserts.

Operating temperature is a critical factor in the performance of cutting tools, and the 2.0-CMW PCD Blank excels in this aspect with an impressive operating temperature capability of up to 700°C. This high thermal tolerance ensures that the PCD Blank can be employed in demanding cutting processes involving elevated temperatures without compromising its structural integrity or performance. Such thermal resilience is crucial in high-speed machining, where heat generation is significant, and tool failure due to overheating can lead to costly production interruptions.

Another notable attribute of the PCD Blank 2.0-CMW is its low conductivity. This characteristic is particularly advantageous in applications where heat dissipation needs to be controlled to prevent thermal damage to the workpiece or the cutting tool itself. By maintaining low thermal conductivity, the PCD Blank helps in managing heat buildup, thereby enhancing the stability and precision of cutting operations. This ensures not only the longevity of the PCD inserts made from this blank but also superior surface finishes on the machined parts.

In the world of PCD tools, the quality and characteristics of the PCD Blank are fundamental to the overall performance of the final product. The 2.0-CMW model stands out as a reliable and high-performance option for manufacturing PCD inserts that are used across various industries, including automotive, aerospace, electronics, and woodworking. Its superior wear resistance, dual bond type options, high operating temperature tolerance, and low conductivity collectively contribute to its reputation as a top-tier PCD Blank.

Moreover, the precision and consistency of the 2.0-CMW PCD Blank enable manufacturers to produce PCD inserts that deliver exceptional cutting accuracy and durability. These inserts are critical in achieving optimal machining results, reducing tool wear, and enhancing overall operational efficiency. The PCD Blank thus plays a crucial role in the production of cutting tools that meet the highest standards of quality and performance.

In conclusion, the PCD Blank 2.0-CMW is an advanced material solution designed to meet the evolving needs of cutting tool manufacturers and end-users. Its superior wear resistance ensures longevity, while the choice between metal or resin bond types provides versatility for various machining applications. The ability to operate at temperatures up to 700°C and its low conductivity further enhance its suitability for high-performance cutting scenarios. As a fundamental component in the creation of PCD inserts and PCD tools, the 2.0-CMW PCD Blank is an indispensable product that drives innovation and efficiency in the cutting tool industry.

Applications:

The CTSTC PCD Blank, model number 1.0-10W, is an exceptional product designed to meet the demanding needs of various industrial applications. As a polycrystalline diamond (PCD) material, it offers superior wear resistance and chemical stability, making it ideal for high-precision cutting, grinding, and machining tasks. With low conductivity and the ability to operate at temperatures up to 700°C, this PCD blank ensures reliable performance even in the most challenging environments.

PCD inserts derived from the CTSTC PCD Blank are widely used in the manufacturing of cutting tools for automotive, aerospace, electronics, and woodworking industries. These industries benefit greatly from the product's outstanding wear resistance and chemical stability, which enhance tool lifespan and reduce downtime. The PCD blank’s ability to maintain performance at elevated temperatures further broadens its application range, enabling high-speed machining and demanding cutting operations.

Thanks to its packaging in a durable plastic box, the CTSTC PCD Blank is protected during transit and storage, ensuring that every unit reaches customers in perfect condition. With a minimum order quantity of just one piece and a negotiable price, it is accessible for businesses of all scales—from small workshops to large manufacturing facilities. The supply capability of 1000 pieces per day and a delivery time of 5-10 days, or 3-7 days after payment, highlight CTSTC’s commitment to prompt order fulfillment and customer satisfaction.

Payment terms such as TT, LC, and Western Union provide flexible options for international buyers, making it convenient to procure these high-quality PCD inserts globally. Whether you require PCD blanks for prototyping, small batch production, or large-scale manufacturing, CTSTC’s product offers the reliability and performance needed to excel in various industrial scenarios.

In summary, the CTSTC PCD Blank is perfectly suited for applications demanding high wear resistance, chemical stability, and operational efficiency at elevated temperatures. It is an essential material for producing PCD inserts used in cutting tools across multiple industries, ensuring precision, durability, and cost-effectiveness in every use.

Support and Services:

Our Product Technical Support and Services for the PCD Blank product are designed to ensure optimal performance and customer satisfaction. We provide comprehensive assistance including installation guidance, troubleshooting, maintenance tips, and software updates. Our technical support team is equipped to help with any product-related inquiries and issues, ensuring minimal downtime and efficient resolution. Additionally, we offer training sessions and detailed documentation to help users maximize the capabilities of their PCD Blank product. For ongoing service, routine inspections and preventive maintenance plans are available to maintain product reliability and longevity.

Packing and Shipping:

Each PCD Blank product is carefully packaged to ensure maximum protection during transit. The product is securely placed in a cushioned, sturdy box to prevent any damage from impact or vibration. All packaging materials used are of high quality and environmentally friendly.

For shipping, we utilize reliable carriers with tracking options to guarantee timely and safe delivery. The PCD Blank products are shipped with appropriate labeling and documentation to comply with all shipping regulations. Customers will receive a tracking number once the product has been dispatched.

We recommend inspecting the package upon arrival and reporting any damage immediately to ensure prompt resolution. Our packaging and shipping process is designed to provide the best possible experience and maintain the integrity of the PCD Blank product.