-

StevenCHN-TOP offer very good service and the products help us a lot

StevenCHN-TOP offer very good service and the products help us a lot -

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines -

MikeBest products with best price, CHN-TOP well done!

MikeBest products with best price, CHN-TOP well done!

High Resolution Laser Sensor CNC Metal Laser Cutter Designed for Metal Processing and Precision Industrial Cutting Tasks

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Lasertype | Fiber Laser | Transmission Mode | Rack And Pinion |

|---|---|---|---|

| Cutting Head | Switerland Raytools | Laser Head | Swiss Raytools Auto-following |

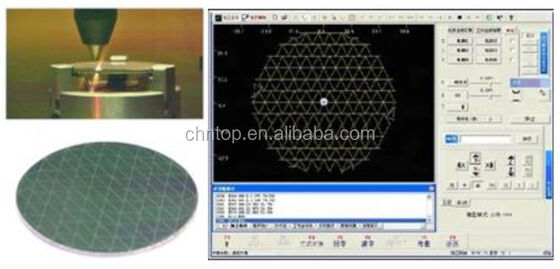

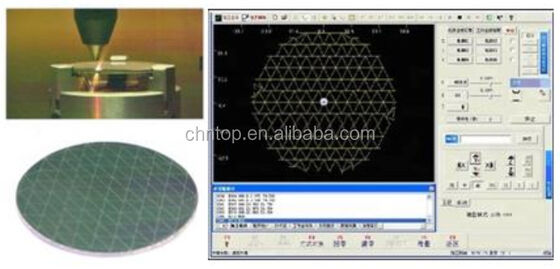

| Focus System | High Resolution Laser Sensor (optional) | Cnc Or Not | CNC |

| Repeatability Accuracy | ±0.02mm | Control System Brand | Cypcut |

| Highlight | high resolution CNC laser cutter,metal processing laser cutting machine,precision industrial fiber laser cutter |

||

Product Description:

The CNC Fiber Laser Cutting Machine is an advanced and highly efficient piece of equipment designed to meet the diverse needs of modern metal fabrication industries. This state-of-the-art cnc metal laser cutter integrates cutting-edge technology with precision engineering, ensuring exceptional performance and reliability for a wide range of metal cutting applications. Whether you are involved in automotive manufacturing, aerospace, electronics, or heavy machinery production, this fiber laser cutting machine offers unparalleled accuracy, speed, and versatility.

At the heart of this machine lies the renowned Cypcut control system, a globally recognized brand known for its user-friendly interface and robust functionality. The Cypcut system enhances the overall efficiency of the fiber laser cutting process by providing precise control over cutting parameters, optimizing cutting paths, and enabling seamless integration with various CAD/CAM software. This powerful control system allows operators to achieve consistent, high-quality cuts with minimal material waste and reduced downtime.

This fiber laser cutting machine utilizes a cutting head from Switzerland’s prestigious Raytools brand, renowned for its durability, precision, and innovative design. The Raytools cutting head ensures stable and accurate laser delivery, which is critical for achieving fine, clean cuts on a variety of metal materials. Its advanced optical system minimizes energy loss, resulting in higher cutting efficiency and better edge quality. The cutting head’s adaptability also allows it to handle different thicknesses and types of metals, making this equipment an indispensable asset in any metalworking workshop.

For users seeking even greater precision, the machine offers an optional high-resolution laser sensor focus system. This advanced focus system automatically detects the surface of the material and adjusts the focal length in real-time to maintain optimal cutting conditions. This feature is particularly beneficial when working with uneven or complex surfaces, ensuring consistent cutting quality and reducing the risk of errors or material damage. The high-resolution laser sensor enhances the machine’s overall productivity and reliability, making it ideal for industries demanding high precision, such as electronics and fine metal fabrication.

Designed primarily for cutting metal materials, this fiber laser cutting machine excels in processing a broad spectrum of metals including stainless steel, carbon steel, aluminum, brass, and copper. Its powerful laser source delivers clean, burr-free cuts that require minimal post-processing, thereby saving time and labor costs. The machine’s capability to handle complex geometries and intricate designs makes it an excellent choice for producing components with tight tolerances and detailed features.

In addition to its cutting capabilities, this fiber laser cutting machine is also recognized as a diamond cutting machine and diamond cutting equipment in the industry, owing to its precision and ability to produce flawless edges akin to diamond-cut finishes. This makes it highly suitable for applications where aesthetics and edge quality are paramount, such as in decorative metalworks, jewelry manufacturing, and high-end architectural components.

Moreover, the fiber laser technology employed in this cnc metal laser cutter offers several advantages over traditional cutting methods. It provides faster cutting speeds, lower operating costs, and reduced environmental impact due to minimal material wastage and energy consumption. The machine’s compact design and user-friendly interface further enhance its appeal, making it accessible for both large-scale industrial operations and smaller workshops seeking to upgrade their cutting capabilities.

In summary, the CNC Fiber Laser Cutting Machine equipped with the Cypcut control system, Switzerland Raytools cutting head, and optional high-resolution laser sensor focus system represents a pinnacle of innovation in fiber laser cutting technology. Its ability to efficiently cut a wide range of metal materials with precision and reliability, combined with its recognition as a diamond cutting machine and diamond cutting equipment, makes it a versatile and invaluable tool for any metal fabrication business. Investing in this machine means embracing cutting-edge technology that boosts productivity, improves product quality, and ultimately drives business growth.

Applications:

The CTSTC ZT-JGQG6S/E CNC Fiber Laser Cutting Machine is an advanced fiber laser cutter designed to meet the demanding needs of various industrial applications. Certified with CE, this fiber CNC laser combines precision, speed, and reliability, making it an ideal choice for metal cutting tasks in manufacturing, fabrication, and engineering workshops.

This diamond cutting machine excels in cutting a wide range of metal materials, including stainless steel, carbon steel, aluminum, copper, and more, with exceptional accuracy and minimal thermal deformation. The integration of the Swiss Raytools auto-following cutting head ensures consistent cutting quality, even on complex or curved surfaces, by automatically adjusting the laser focal point in real-time.

With a working speed of up to 8 meters per minute, the CTSTC ZT-JGQG6S/E significantly enhances productivity, allowing businesses to complete jobs faster without compromising on precision. Its CNC control system enables automated cutting processes, reducing manual labor and improving repeatability for batch production.

The machine is ideal for occasions such as industrial metal fabrication, automotive part manufacturing, aerospace component production, and custom metal artwork creation. It is also perfect for small to large scale workshops that require a reliable fiber laser cutter capable of handling diverse cutting requirements with ease.

Packaged securely in a sturdy plywood box, the CTSTC CNC fiber laser cutter is shipped with care to ensure safe delivery within 45-60 days. The minimum order quantity is just one unit, making it accessible for businesses of varying sizes. Payment is facilitated through TT terms, providing convenience and security in transactions.

Overall, the CTSTC ZT-JGQG6S/E diamond cutting machine stands out in the market as a high-performance fiber laser cutter, combining Swiss precision with robust CNC technology. Whether for precision metal cutting or high-speed production, this fiber CNC laser is a reliable solution tailored to meet modern industrial demands.

Customization:

CTSTC offers customized Product Customization Services for the CNC Fiber Laser Cutting Machine, model ZT-JGQG6S/E, designed to meet your unique manufacturing needs. As a certified CE diamond cutting equipment provider, we ensure that every fiber laser cutter is crafted with precision and reliability.

Our fiber laser cutting machine features a high-performance PRECITEC laser cutting head from Germany, combined with advanced CNC technology and a rack and pinion transmission mode to deliver a working speed of 8 meters per minute. This guarantees exceptional cutting accuracy and efficiency for various industrial applications.

We accept a minimum order quantity of just 1 unit, allowing businesses of all sizes to benefit from our state-of-the-art fiber laser cutter. Each machine is securely packaged in a durable plywood box to ensure safe delivery within 45-60 days after order confirmation.

Payment terms are flexible with TT options available to facilitate smooth transactions. Trust CTSTC for tailored customization solutions that enhance your production capabilities with top-quality diamond cutting equipment and fiber laser cutting machines.

Support and Services:

Our CNC Fiber Laser Cutting Machine is designed to deliver high precision and efficiency for various cutting applications. To ensure optimal performance and longevity of your machine, we offer comprehensive technical support and services.

Our technical support team is available to assist you with installation guidance, machine setup, troubleshooting, and routine maintenance advice. We provide detailed user manuals and operation guides to help you understand the functionalities and safety precautions of the equipment.

We also offer training programs for operators and technicians to maximize the machine’s capabilities and ensure safe handling. Our service includes regular software updates and hardware upgrade options to keep your machine up-to-date with the latest technological advancements.

In case of any technical issues, our support staff can provide remote assistance or arrange on-site service to minimize downtime. We maintain a stock of genuine spare parts to ensure quick replacements and repairs.

Our goal is to provide reliable and responsive support to help you achieve the best results with your CNC Fiber Laser Cutting Machine and maintain continuous production efficiency.