-

StevenCHN-TOP offer very good service and the products help us a lot

StevenCHN-TOP offer very good service and the products help us a lot -

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines -

MikeBest products with best price, CHN-TOP well done!

MikeBest products with best price, CHN-TOP well done!

760 Degree Vacuum Brazing Paste Grey Paste Specific Gravity 2.5-3.0 G/cm3 for Temperature Brazing

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Flux | Color | Brown |

|---|---|---|---|

| Package | Syringe/Tube | Certifications | ISO 9001, RoHS |

| Form | Paste | Appearance | Grey Paste |

| Melting Point | 800-1000°C | Package Size | 100g |

| Highlight | 760 degree vacuum brazing paste,vacuum brazing paste grey,vacuum brazing paste specific gravity 2.5 |

||

Product Description:

With a viscosity range of 10-20 Pa.s, this Vacuum Brazing Paste is formulated to provide excellent flow properties, ensuring uniform coverage and optimal adhesion between the brazing surfaces. Its unique composition of silver, copper, and indium contributes to its superior bonding strength and thermal conductivity, making it suitable for a wide range of brazing applications.

As a Flux-based material, this Vacuum Brazing Paste is specifically designed to facilitate the brazing process by promoting the wetting and spreading of the braze alloy on the base metals. The flux component helps remove oxides and contaminants from the metal surfaces, ensuring clean and reliable joints.

Featuring a melting point range of 800-1000°C, this Vacuum Brazing Paste is capable of creating strong and durable bonds between metal substrates, even under high-temperature conditions. Its grey paste appearance provides visual indication of proper application and distribution, allowing for easy monitoring during the brazing process.

Whether used in aerospace, automotive, or other industrial applications, this Vacuum Brazing Paste offers consistent and precise results, thanks to its carefully balanced formulation and quality manufacturing processes. The fine particle size of the braze alloy components ensures smooth and uniform application, leading to high-quality brazed joints with minimal defects.

When applied in a vacuum brazing environment, this specialized paste transforms into a gel-like consistency, ensuring excellent coverage and penetration into tight spaces between the mating surfaces. The gel-like nature of the paste enhances its ability to fill gaps and imperfections, resulting in strong and reliable bonds that meet the stringent requirements of demanding applications.

Overall, the Vacuum Brazing Paste is a versatile and dependable product that delivers exceptional performance in vacuum brazing operations. Its high-purity composition, precise viscosity range, and Flux-based formulation make it an indispensable tool for achieving superior brazed joints with excellent mechanical and thermal properties.

Technical Parameters:

| Tensile Strength | 455 MPa |

| Brazing Temperature | 760 Degree |

| Composition | Silver, Copper, Indium |

| Melting Point | 800-1000°C |

| Certifications | ISO 9001, RoHS |

| Model No | 800-41 |

| Package | Syringe/Tube |

| Material | Flux |

| Appearance | Grey Paste |

| Application | Brazing Of Metal Materials |

Applications:

CTSTC's Vacuum Brazing Paste, model number 800-41, is a high-quality product designed for various brazing applications in the metalworking industry. With a minimum order quantity of 10 grams and negotiable pricing, this product comes in convenient packaging details of a syringe, allowing for easy application.

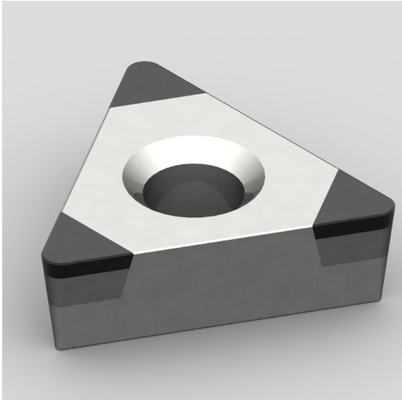

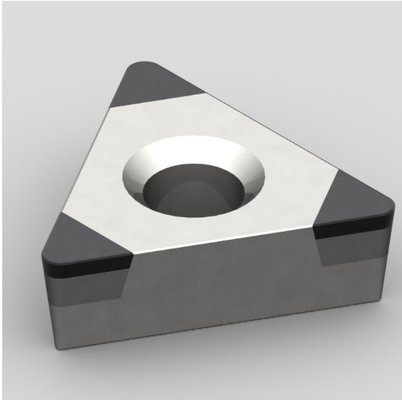

One of the key features of this brazing paste is its suitability for use in brazing of metal materials, making it an ideal choice for industries working with PCD/PCBN tools. The paste has a viscosity range of 10-20 Pa.s, ensuring smooth application and adherence to the materials being brazed.

The Vacuum Brazing Paste from CTSTC has a melting point between 800-1000°C, with a brazing temperature of 760 degrees, providing optimal conditions for strong and durable bonds. Its supply ability of 1000 grams per day ensures a reliable source for your brazing needs, with delivery times ranging from 5-10 days.

Whether you are working on vacuum welding applications or require a vacuum brazing adhesive for precision work, the CTSTC Vacuum Brazing Paste, model 800-41, offers a versatile solution. Payment terms include TT, LC, and Western Union, providing flexibility for your purchasing process.

Customization:

Product Customization Services for Vacuum Brazing Paste

Brand Name: CTSTC

Model Number: 800-41

Minimum Order Quantity: 10 gram

Price: Negotiable

Packaging Details: Syringe

Delivery Time: 5-10 Days

Payment Terms: TT/LC/Western Union

Supply Ability: 1000 gram/day

Package: Syringe/Tube

Viscosity: 10-20 Pa.s

Tensile Strength: 455 MPa

Brazing Temperature: 760 Degree

Material: Flux

Support and Services:

Our Product Technical Support and Services for the Vacuum Brazing Paste include: - Providing guidance on the proper application and usage of the paste - Offering troubleshooting assistance for any issues that may arise during the brazing process - Conducting training sessions for customers to improve their brazing skills - Collaborating with customers to develop custom brazing solutions tailored to their specific needs - Keeping customers informed about any product updates or enhancements that may benefit their operations