-

StevenCHN-TOP offer very good service and the products help us a lot

StevenCHN-TOP offer very good service and the products help us a lot -

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines -

MikeBest products with best price, CHN-TOP well done!

MikeBest products with best price, CHN-TOP well done!

Original Vacuum Brazing Paste with Electrical Conductivity of 9.4 X 106 /ohm∙m and Temperature Range of 600-800°C

| Form | Paste | Quality Guarranty | 6 Month |

|---|---|---|---|

| Package Size | 1 Lb Jar | Electrical Conductivity | 9.4 X 106 /ohm∙m |

| Package | Vacuum Tube | Certifications | ISO 9001, RoHS |

| Original | USA | Guarranty | 6 Month |

| Highlight | vacuum brazing paste for PCD,high-temperature vacuum brazing paste,Original Vacuum Brazing Paste |

||

| Attribute | Value |

|---|---|

| Form | Paste |

| Quality Guarantee | 6 Month |

| Package Size | 1 Lb Jar |

| Electrical Conductivity | 9.4 X 106 /ohm∙m |

| Package | Vacuum Tube |

| Certifications | ISO 9001, RoHS |

| Original | USA |

| Guarantee | 6 Month |

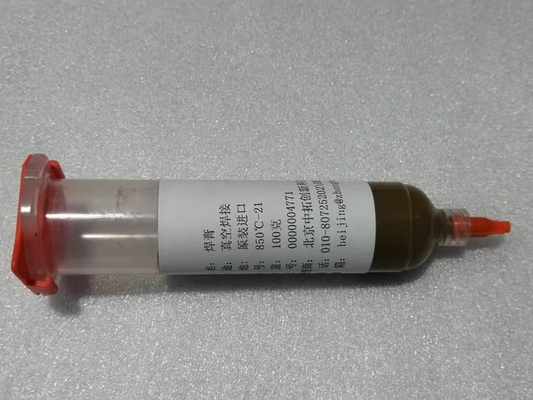

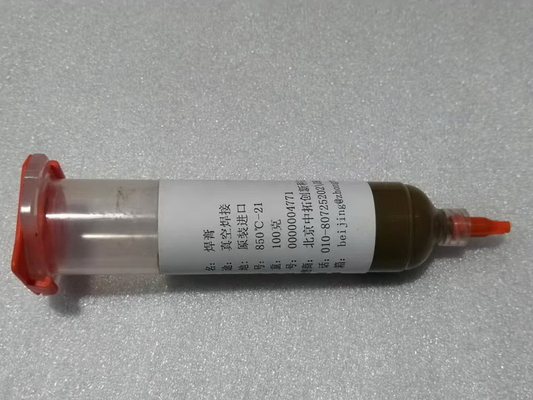

The Vacuum Brazing Paste is a high-quality product designed for brazing PCD/PCBN materials in various industrial applications. This Vacuum Brazing Paste Compound is manufactured in the USA, ensuring top-notch quality and performance. It comes with a guarantee of 6 months, giving you peace of mind regarding its reliability and durability.

The Vacuum Brazing Paste is packed in a convenient plastic tube, making it easy to store and apply. The packaging ensures the longevity of the product, protecting it from external elements that may affect its performance. This user-friendly design allows for precise application and minimizes waste, making it a cost-effective choice for your brazing needs.

With a temperature range of 600-800°C, this Vacuum Brazing Paste is suitable for a wide range of brazing applications. Whether you are working with PCD or PCBN materials, this brazing paste provides a reliable bond at the specified temperature range. The consistency of the paste ensures uniform distribution, resulting in strong and durable bonds that meet your requirements.

Featuring a density of 9.7 Mg/m³, this Vacuum Brazing Paste offers excellent flow properties, allowing for easy application and uniform coverage. The optimal density of the paste ensures that it adheres well to the surfaces being brazed, creating a secure bond that enhances the overall performance of the materials.

The CTSTC 800-41 Vacuum Brazing Paste is a high-quality product designed for various product application occasions and scenarios where vacuum welding mixture or vacuum brazing solution is required. This brazing paste, specifically formulated for PCD (polycrystalline diamond) and PCBN (polycrystalline cubic boron nitride) materials, offers exceptional performance and reliability.

Whether you are working in the automotive industry, aerospace sector, or tool manufacturing field, the CTSTC 800-41 Vacuum Brazing Paste is an ideal choice for your brazing needs. Its unique formulation ensures strong and durable bonds, making it suitable for a wide range of applications.

With a minimum order quantity of 10 grams and negotiable pricing, this product comes in convenient syringe packaging, allowing for easy application and storage. The delivery time is quick, with orders typically shipped within 5-10 days. Payment terms are flexible, including TT, LC, and Western Union.

Customize your Vacuum Brazing Paste product from CTSTC with the following options:

- Brand Name: CTSTC

- Model Number: 800-41

- Minimum Order Quantity: 10gram

- Price: Negotiable

- Packaging Details: Syringe

- Delivery Time: 5-10 Days

- Payment Terms: TT/LC/Western Union

- Supply Ability: 1000gram/day

- Packing: Plastic Tube

- Certifications: ISO 9001, RoHS

- Specific Gravity: 8.8 G/cm3

- Density: 9.7 Mg/m³

- Electrical Conductivity: 9.4 X 106 /ohm∙m

Customization options available for Vacuum Brazing Solution, Vacuum Brazing Gel, and Vacuum Brazing Paste Compound.

The Vacuum Brazing Paste product offers comprehensive Product Technical Support and Services to ensure the efficient and effective use of the product. Our team of experts is dedicated to providing guidance on product application, troubleshooting, and optimization to meet the specific needs of our customers. Additionally, we provide training and education programs to enhance product understanding and maximize performance.