-

StevenCHN-TOP offer very good service and the products help us a lot

StevenCHN-TOP offer very good service and the products help us a lot -

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines -

MikeBest products with best price, CHN-TOP well done!

MikeBest products with best price, CHN-TOP well done!

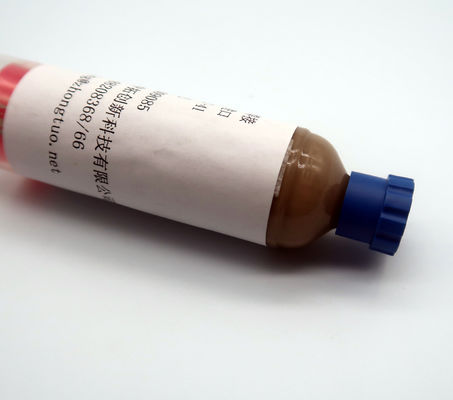

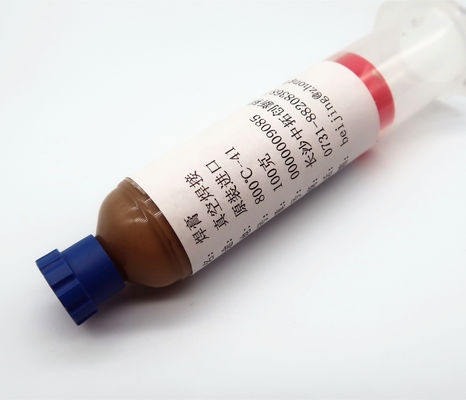

100g Vacuum Brazing Paste for Brazing Of Metal Parts with High Tensile Strength 455 MPa

| Density | 9.7 Mg/m³ | Shelf Life | 12 Months |

|---|---|---|---|

| Electrical Conductivity | 9.4 X 106 /ohm∙m | Form | Paste |

| Model | 800-41 | Package | Vacuum Tube |

| Active Temperature | 760℃ | Application | Brazing Of Metal Parts |

| Highlight | Carbide Materials Vacuum Brazing Paste,100g Vacuum Welding Paste,PCB Materials Vacuum Brazing Paste |

||

Product Description:

Are you tired of dealing with traditional brazing methods that leave your metal parts with weak joints and poor electrical conductivity? Look no further! Our Vacuum Brazing Paste is here to revolutionize your brazing experience with its exceptional properties.

Our Vacuum Brazing Paste is a high-purity active braze alloy specially designed for brazing of metal parts. It is a unique vacuum brazing adhesive that offers superior electrical conductivity and high-temperature resistance, making it the perfect solution for your brazing needs.

The Vacuum Brazing Paste comes in a paste form, making it easy to apply and ensuring a smooth and even coating on your metal parts. Its thick consistency allows for better adhesion, ensuring a strong and reliable bond between the parts.

The paste has a low electrical resistivity of 106 X 10-9 Ohm∙m, making it an ideal choice for applications that require excellent electrical conductivity. It ensures a stable flow of electricity through the joints, making it suitable for electronic components and other sensitive devices.

With a high electrical conductivity of 9.4 X 106 /ohm∙m, our Vacuum Brazing Paste outperforms traditional brazing methods, which often result in poor electrical conductivity. It ensures a strong and stable connection between the metal parts, allowing for efficient transfer of electricity.

The Vacuum Brazing Paste can withstand temperatures ranging from 715-1319℃, making it suitable for high-temperature applications. Its superior temperature resistance ensures that the bond remains strong even under extreme heat, providing a long-lasting and reliable joint.

- High-purity active braze alloy

- Vacuum brazing adhesive

- Superior electrical conductivity

- High-temperature resistance

Upgrade your brazing process with our Vacuum Brazing Paste and experience the difference in quality and performance. Its unique properties make it the ultimate solution for all your brazing needs. Order now and see the results for yourself!

Features:

- Product Name: Vacuum Brazing Paste

- Tensile Strength: 455 MPa

- Electrical Resistivity: 106 X 10-9 Ohm∙m

- Active Temperature: 760℃

- Color: Brown

- Quality Guarranty: 6 Month

- Vacuum Brazing Paste

- Vacuum Brazing Gel

- Vacuum Welding Paste

- 455 MPa

- 106 X 10-9 Ohm∙m

- 760℃

- Brown

- 6 Month

Technical Parameters:

| Attribute | Value |

|---|---|

| Coefficient of Thermal Expansion | 18.2 X 10-6 /C, For 20 – 400 °C |

| Composition | Silver, Copper, Indium |

| Form | Paste |

| Electrical Conductivity | 9.4 X 106 /ohm∙m |

| Model | 800-41 |

| Density | 9.7 Mg/m³ |

| Color | Brown |

| Package Size | 100g |

| Package | Vacuum Tube |

| Electrical Resistivity | 106 X 10-9 Ohm∙m |

| Product Name: | Vacuum Brazing Paste |

| Product Type: | Brazing Paste For Carbide |

| Composition: | High-purity Active Braze Alloy (Silver, Copper, Indium) |

| Form: | Paste |

| Coefficient of Thermal Expansion: | 18.2 X 10-6 /C, For 20 – 400 °C |

| Electrical Conductivity: | 9.4 X 106 /ohm∙m |

| Model: | 800-41 |

| Density: | 9.7 Mg/m³ |

| Color: | Brown |

| Package Size: | 100g |

| Package: | Vacuum Tube |

| Electrical Resistivity: | 106 X 10-9 Ohm∙m |

| Application: | Vacuum Brazing Solution |

Applications:

Brazing is a process of joining two metal pieces together by melting a filler metal that has a lower melting point than the base metals. Vacuum brazing is a specialized type of brazing that utilizes a vacuum environment to prevent oxidation and ensure a clean and strong joint. CTSTC's Vacuum Brazing Paste is specifically designed for this process, providing high-strength joints and high temperature resistance for various applications.

- Brand Name: CTSTC

- Model Number: 800-41

- Place of Origin: China

- Minimum Order Quantity: 10 grams

- Price: Negotiable

- Packaging Details: Syringe

- Delivery Time: 5-10 days

- Payment Terms: TT/LC/Western Union

- Supply Ability: 1000 grams per day

- Model: 800-41

- Coefficient of Thermal Expansion: 18.2 X 10-6 /C, For 20 – 400 °C

- Shelf Life: 12 months

- Quality Guarantee: 6 months

- Electrical Conductivity: 9.4 X 106 /ohm•m

CTSTC's Vacuum Brazing Paste is ideal for brazing carbide materials, providing a strong and durable joint. The paste is made with a high-purity active braze alloy, ensuring a clean and reliable bond. Its high temperature resistance makes it suitable for use in various industries such as aerospace, automotive, and electronics.

The Vacuum Brazing Paste is easy to apply with a syringe packaging, making it convenient for use in both small and large-scale productions. Its quick-drying formula allows for fast and efficient brazing, saving time and increasing productivity.

CTSTC's Vacuum Brazing Paste is suitable for various applications, including:

- Brazing of carbide cutting tools for the metalworking industry

- Brazing of heat exchangers and other components for the aerospace industry

- Brazing of electrical components for the electronics industry

- Brazing of automotive parts such as engine valves and exhaust systems

- Brazing of heat-resistant parts for high-temperature furnaces

With its high-strength joints and high temperature resistance, CTSTC's Vacuum Brazing Paste is a reliable and efficient solution for all your brazing needs. Contact us now to place your order and experience the quality and durability of our products.

| Property | Value |

|---|---|

| Brand Name | CTSTC |

| Model Number | 800-41 |

| Place of Origin | China |

| Minimum Order Quantity | 10 grams |

| Price | Negotiable |

| Packaging Details | Syringe |

| Delivery Time | 5-10 days |

| Payment Terms | TT/LC/Western Union |

| Supply Ability | 1000 grams per day |

| Model | 800-41 |

| Coefficient of Thermal Expansion | 18.2 X 10-6 /C, For 20 – 400 °C |

| Shelf Life | 12 months |

| Quality Guarantee | 6 months |

| Electrical Conductivity | 9.4 X 106 /ohm•m |

Customization:

Brand Name: CTSTC

Model Number: 800-41

Place of Origin: China

Minimum Order Quantity: 10gram

Price: Negotiable

Packaging Details: Syringe

Delivery Time: 5-10 days

Payment Terms: TT/LC/Western Union

Supply Ability: 1000gram/day

Coefficient of Thermal Expansion: 18.2 X 10-6 /C, For 20 – 400 °C

Electrical Resistivity: 106 X 10-9 Ohm∙m

Electrical Conductivity: 9.4 X 106 /ohm∙m

Shelf Life: 12 Months

Density: 9.7 Mg/m³

At CTSTC, we understand that every customer has unique needs and requirements. That's why we offer a customization service for our Vacuum Brazing Paste Compound, suitable for various applications including PCD/PCBN and Carbide materials.

Our Brazing Paste can be customized according to your specifications, ensuring the best performance for your specific application. Our team of experts will work closely with you to determine the right composition and parameters for your needs.

CTSTC is a leading brand in the vacuum brazing industry, known for its high-quality products and exceptional customer service. With years of experience and a team of skilled professionals, we are committed to providing the best solutions for our customers.

The 800-41 model is a popular choice among our customers, known for its excellent thermal and electrical conductivity. With a coefficient of thermal expansion of 18.2 X 10-6 /C and an electrical resistivity of 106 X 10-9 Ohm∙m, this model is suitable for a wide range of applications.

All our products are proudly made in China, ensuring high-quality standards and competitive prices.

Our minimum order quantity is 10 grams, making it easy for customers to try out our products without committing to a large quantity. We also offer negotiable prices, ensuring that all our customers get the best value for their money.

To ensure the safety and integrity of our products during transportation, we use secure syringe packaging. This also makes it easy for our customers to use the product without any spills or waste.

With a dedicated team and efficient processes, we can deliver your order within 5-10 days, ensuring that you get your product on time for your project.

We offer flexible payment terms including TT, LC, and Western Union, making it convenient for our customers to complete their transactions.

With a supply ability of 1000 grams per day, we can fulfill large orders and meet the demands of our customers.

- High Thermal Conductivity: Our brazing paste has a high coefficient of thermal expansion, making it suitable for applications requiring high thermal conductivity.

- Low Electrical Resistivity: With a low electrical resistivity, our product can efficiently conduct electricity, making it suitable for various electrical applications.

- High Shelf Life: Our brazing paste has a shelf life of 12 months, ensuring its quality and effectiveness for a long period of time.

- High Density: With a density of 9.7 Mg/m³, our product is durable and resistant to wear and tear.

Packing and Shipping:

Vacuum Brazing Paste is carefully packaged and shipped to ensure its high quality and protection during transit.

The product is packed in airtight containers to prevent air and moisture from affecting its performance. These containers are then placed in sturdy cardboard boxes for additional protection. Each box is labeled with the product name, quantity, and any necessary safety warnings.

Vacuum Brazing Paste is shipped using reliable and efficient methods to ensure timely delivery. The shipping method will depend on the size and quantity of the order, as well as the delivery location. Our team carefully monitors each shipment to ensure it arrives in perfect condition.

For international shipments, additional precautions are taken to comply with customs regulations and ensure a smooth delivery process. Any necessary documentation will be included with the shipment.

In the unlikely event of any damage or issues with the shipment, please contact our customer service team immediately for assistance.

FAQ:

- Q: What is the brand name of this product?

A: The brand name of this product is CTSTC. - Q: What is the model number of this product?

A: The model number of this product is 800-41. - Q: Where is this product manufactured?

A: This product is manufactured in China. - Q: What is the minimum order quantity for this product?

A: The minimum order quantity for this product is 10 grams. - Q: Is the price of this product negotiable?

A: Yes, the price of this product is negotiable. - Q: How is this product packaged?

A: This product is packaged in syringes. - Q: What is the estimated delivery time for this product?

A: The estimated delivery time for this product is 5-10 days. - Q: What are the accepted payment terms for this product?

A: The accepted payment terms for this product are TT, LC, and Western Union. - Q: How much of this product is available for supply per day?

A: The supply ability for this product is 1000 grams per day.