-

StevenCHN-TOP offer very good service and the products help us a lot

StevenCHN-TOP offer very good service and the products help us a lot -

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines -

MikeBest products with best price, CHN-TOP well done!

MikeBest products with best price, CHN-TOP well done!

Automatic Metal CNC Fiber Laser Cutting Machine, Water Cooling PCD/PCBN Cutter

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Metal Fiber Laser Cutting Machine Automatic PCD/PCBN Cutter | Cooling Mode | Water Cooling |

|---|---|---|---|

| Table Travel | 220*220*100mm (X*Y*Z) | Guarranty | 2 Years |

| Application | PCD/PCBN Cutting | Condition | New |

| Model | 2022 Mode | After-sales Service Provided | Engineers Available To Service Machinery Overseas |

| Highlight | 4 Axis CNC Fiber Laser Cutting Machine,0.005mm CNC Fiber Laser Cutting Machine,PCD CNC Fiber Laser Cutter |

||

Metal Fiber Laser Cutting Machine Automatic PCD/PCBN Cutter

Originally founded by graduates from Tsinghua University, CHN-TOP SCI & TECH CO., LTD. is a high-tech enterprise specialized in diamond tools (PCD, PCBN, MD, ND, CVD) industries, producing high precision processing equipments (PCD/PCBN tools'grinders, vacuum brazing machines, laser

cutting and engraving machines, laser processing center). We offer pre-machining services (PCD/PCBN laser cutting, tools brazing, chip breaker engraving, lapping and polishing, etc. ), and distribute world famous PCD/PCBN blanks. Also supply professional consultation and advanced technical services. We are your only one stop factory in the field of ultra-hard materials processing with a good reputation in the global market.

![]()

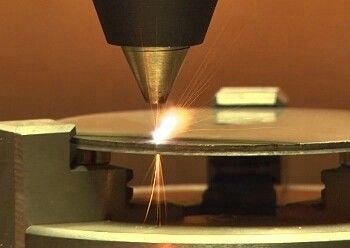

ZT-JGQG6S is a new model of laser cutting machine. The self-developed laser source makes better cutting performance, completely replaced the traditional YAG cutting machine. Higher cutting speed and thinner cutting kerf (2.0mm thickness PCD, the cutting kerf is 0.06-0.08mm), smooth cutting surface, running steady and maintenance-free. Suitable for cutting PCD/PCBN/CVD/Sapphire/ PDC/Cemented Carbide/Ceramics and other precious and ultra-hard materials. Especially, it has incomparable advantages in cutting low content PCBN.

![]()

Design Features:

• Marble base table, not affected by temperature and humidity, stable and not easy to deform.

• Adopts advanced fiber laser module, more stable, more precise, more durable and

maintenance-free.

• The self-developed laser source, minimum after-sales service cost.

• High efficiency, high precision cutting, thin cutting kerf, saves the material.

• 3 times faster cutting speed than YAG, with smaller heat-affected zone.

• Two axis of the worktable are driven by servo motor, closed-loop control, repositioning accuracy :s:0.005mm.

• 24 hours working, processing any 2D graphics, software supports automatic model and manual model, equipped with CCD monitor.

• Z axis step motor drive and A axis as rotary axis, can process the material with relief angle.

![]()

![]()

![]()

![]()

Technical Parameters:

|

Power supply requirements |

380V50Hz, Five-core four-square power cord |

|

Working environment |

Room temperature 20~40℃, humidity ≦60%, away from oil source |

|

Cooling Mode of Machine |

Adopt dual temperature cooling system , laser cutting head cooled by room temperature water. Laser cooled by 22℃cooling circulating water, and for manufacturing workpiece cooled by purify oil-free compressed air. |

|

Laser Source |

Fiber laser |

|

Duty Ratio |

1~100% |

|

Frequency |

1-2000 Hz |

|

Power percentage |

1%~100% |

|

Four Axis stroke |

300*300*50mm A-Axis 0±30° |

|

Maximun power output |

3000W |

|

Positioning accuracy |

≦± 0.005mm |

|

Repeat positioning accuracy |

≦± 0.005mm |

Q: Are you trading company or manufacturer ?

A: We are manufactory for PCD,CBN diamond tools equipments and service, we have our own R&D team and production workshop. We can develop our customers' unique products according to their needs.

Q: How about your after-sales system?

A: We have a comprehensive after-sales system, which can provide one-on-one online video service according to the needs of customers, and one-on-one service to solve customers' worries.

Q: How about the cutting thickness and width of Laser cutting machine?

A: 1), Cutting thickness, single-sided cutting maximum thickness of 4-5mm, double-sided cutting maximum thickness of 8 10mm.

2), Slit width: 0.05-0.15mm, accuracy can reach 0.01mm.