-

StevenCHN-TOP offer very good service and the products help us a lot

StevenCHN-TOP offer very good service and the products help us a lot -

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines -

MikeBest products with best price, CHN-TOP well done!

MikeBest products with best price, CHN-TOP well done!

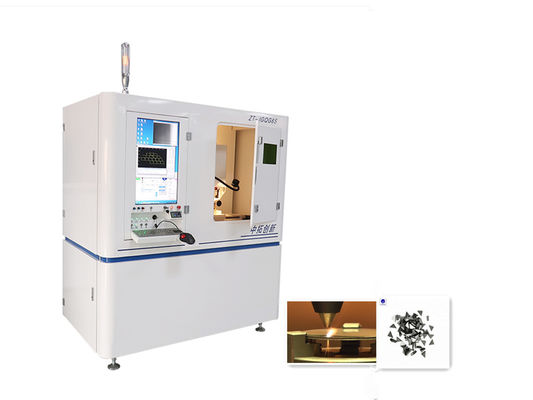

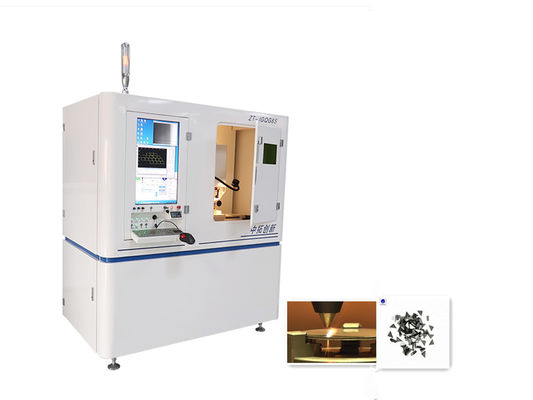

Self Developed Ultra Hard Material Cutting Machine 380V CE certified

| Product Name | CHN-TOP Self-developped Ultra Hard Material Cutting Machine With 2 Years Gurranty | Dimension | 1500*920*1640mm |

|---|---|---|---|

| Power | 380V | Cooling Mode | Water Cooling |

| Cnc Or Not | Yes | Guarranty | 2 Years |

| Key Word | PCD/PCBN Cutter | Condition | New |

| Model | 2022 Mode | After-sales Service Provided | Engineers Available To Service Machinery Overseas |

| Highlight | 380V Fiber Laser Material Cutting Machine,CE Fiber Laser Cutting Machine,CE Certified CNC Material Cutting Machine |

||

CHN-TOP Self-developped Ultra Hard Material Cutting Machine With 2 years gurranty

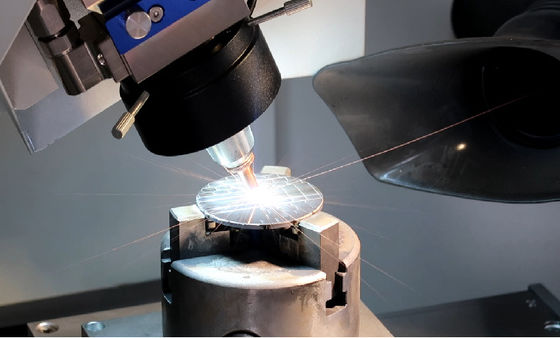

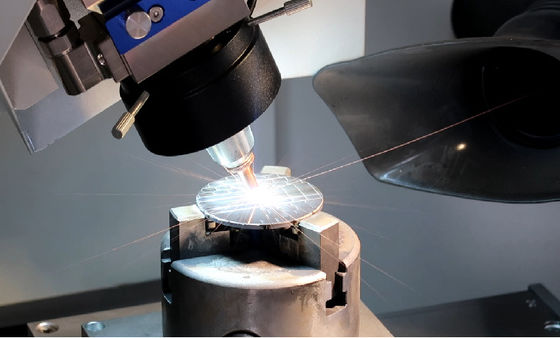

ZT-JGQG6S is a new model of laser cutting machine. The self-developed laser source makes better cutting performance, completely replaced the traditional YAG cutting machine. Higher cutting speed and thinner cutting kerf (2.0mm thickness PCD, the cutting kerf is 0.06-0.08mm), smooth cutting surface, running steady and maintenance-free. Suitable for cutting PCD/PCBN/ CVD/Sapphire/ PDC/ Cemented Carbide/Ceramics and other precious and ultra-hard materials. Especially, it has incomparable advantages in cutting low content PCBN.

![]()

Marble base table, not affected by temperature and humidity, stable and not easy to deform.

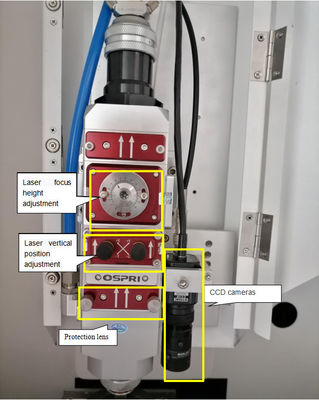

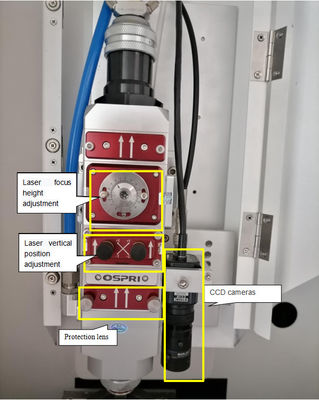

Adopts advanced fiber laser module, more stable, more precise, more durable and

maintenance-free.

The self-developed laser source, minimum after-sales service cost.

High efficiency, high precision cutting, thin cutting kerf, saves the material.

3 times faster cutting speed than YAG, with smaller heat-affected zone.

Two axis of the worktable are driven by servo motor, closed-loop control, repositioning accuracy :s:0.005mm.

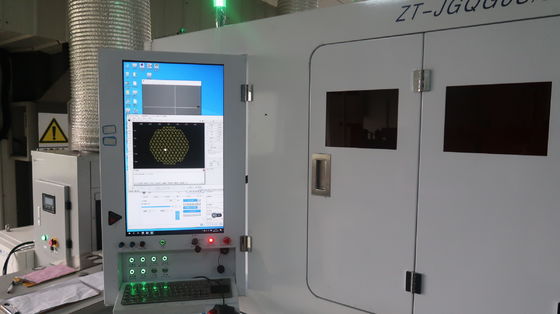

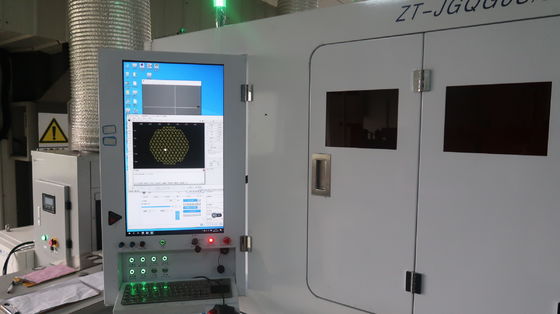

24 hours working, processing any 2D graphics, software supports automatic model and manual model, equipped with CCD monitor.

Z axis step motor drive and A axis as rotary axis, can process the material with relief angle.

![]()

![]()

![]()

Technical Parameters:

|

Power supply requirements |

380V50Hz, Five-core four-square power cord |

|

Working environment |

Room temperature 20~40℃, humidity ≦60%, away from oil source |

|

Cooling Mode of Machine |

Adopt dual temperature cooling system , laser cutting head cooled by room temperature water. Laser cooled by 22℃cooling circulating water, and for manufacturing workpiece cooled by purify oil-free compressed air. |

|

Laser Source |

Fiber laser |

|

Duty Ratio |

1~100% |

|

Frequency |

1-2000 Hz |

|

Power percentage |

1%~100% |

|

Four Axis stroke |

300*300*50mm A-Axis 0±30° |

|

Maximun power output |

3000W |

|

Positioning accuracy |

≦± 0.005mm |

|

Repeat positioning accuracy |

≦± 0.005mm |