-

StevenCHN-TOP offer very good service and the products help us a lot

StevenCHN-TOP offer very good service and the products help us a lot -

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines

S.N. SharmaCHN-TOP machine help me to improve my imprresion for Chinese machines -

MikeBest products with best price, CHN-TOP well done!

MikeBest products with best price, CHN-TOP well done!

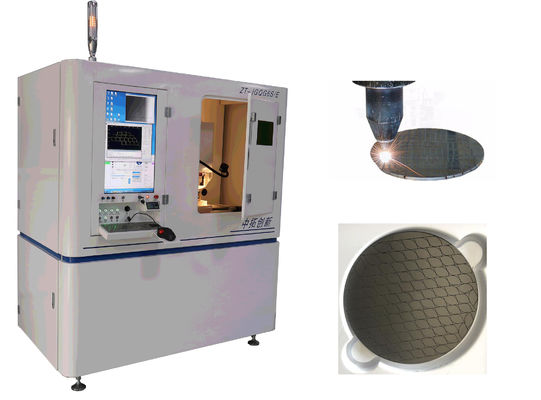

CNCc 1500x920x1640mm Fiber Metal Laser Cutting Machine 380v With FDA Certification

| Application | PCD/PCBN Cutter | Model | 2022 New |

|---|---|---|---|

| Certificate | CE, FDA | Product Name | Fiber Metal Laser Cutting Machine With Comptitive Price And Maintance Free |

| Laser Source | Fiber | Dimension | 1500*920*1640mm |

| Power | 380V | After-sales Service | 2 Years |

| Highlight | 380V Fiber Metal Laser Cutting Machine,FDA Fiber Metal Laser Cutting Machine,CNC Fiber Metal Laser Cutting Machine |

||

Fiber Metal Laser Cutting Machine With Comptitive Price And Maintance Free

![]()

![]()

![]()

![]()

Technical Parameters:

|

Power supply requirements |

380V50Hz, Five-core four-square power cord |

|

Working environment |

Room temperature 20~40℃, humidity ≦60%, away from oil source |

|

Cooling Mode of Machine |

Adopt dual temperature cooling system , laser cutting head cooled by room temperature water. Laser cooled by 22℃cooling circulating water, and for manufacturing workpiece cooled by purify oil-free compressed air. |

|

Laser Source |

Fiber laser |

|

Duty Ratio |

1~100% |

|

Frequency |

1-2000 Hz |

|

Power percentage |

1%~100% |

|

Four Axis stroke |

300*300*50mm A-Axis 0±30° |

|

Maximun power output |

3000W |

|

Positioning accuracy |

≦± 0.005mm |

|

Repeat positioning accuracy |

≦± 0.005mm |

Daily maintenance and maintenance

1. Check the operation of the laser carefully before turn on daily, check the equipment button indicator lamp, stop the ammonium button key switch is not normal.

2. check the circulating water level of water cooler water tank, if not added in time.

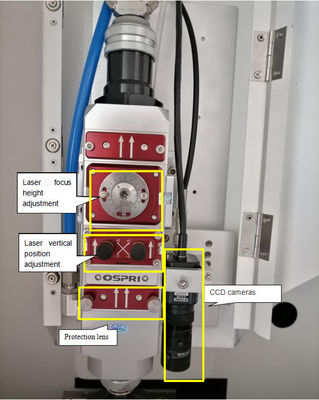

3. Check protective lens for damage before daily cutting.

4. Clean up the dust and debris inside the worktable after each shift is completed.

5. After one year of using , the machine tool and worktable should be adjusted regularly to ensure the cutting accuracy of the machine tool.

If the equipment is not in use for a long time, please apply butter to the moving parts and rust-prone parts of the machine tool to prevent rust.